How To Stagger Vinyl Plank Flooring

Video How to lay vinyl plank flooringVinyl planks are all exactly the same size, unlike the random length hardwood planks. This can lead to weird, eye-catching, and never-so-great coupling patterns. Hence the question: “How do I stagger vinyl flooring?” Reading: How to stagger vinyl flooring. Get the right vinyl plank flooring structure and the people you get it won’t consider you could have done it yourself. In general, what would you note? tools and supplies you will need for this course in addition to typical cost for all goods. We can even break step one what you will need to do with a viewfinder to get your vinyl floor leveled correctly. Staggered vinyl flooring preserves the structural integrity of the ground, reducing the risk of plank-like spots warping, splitting, or warping.

Tools, Supply and Prices

Contents

Read more: Pocket juice how to chargeTool:

- Utility Knife: $7-$12

- Replacement blades: $3-$6 per pack

- Tape Measure: $5-$15

- Straight edge or T-shaped: $12-$25

- Pads: $3 – $5 per 200 . pack

- Security Gloves: $4 – $10

Provided:

- Vinyl Flooring: $1.30- $4.19 per square ft.

Step by step process

Preparatory steps to put together for amazing flooring

With these necessary steps, a little shine may be removed from your vinyl plank flooring patterns.

Also, find out the installation materials that come with the flooring. It will prompt you to do things like use a 1/4 inch spacer between the planks and the bulkhead.

Steps to make incredible vinyl plank flooring:

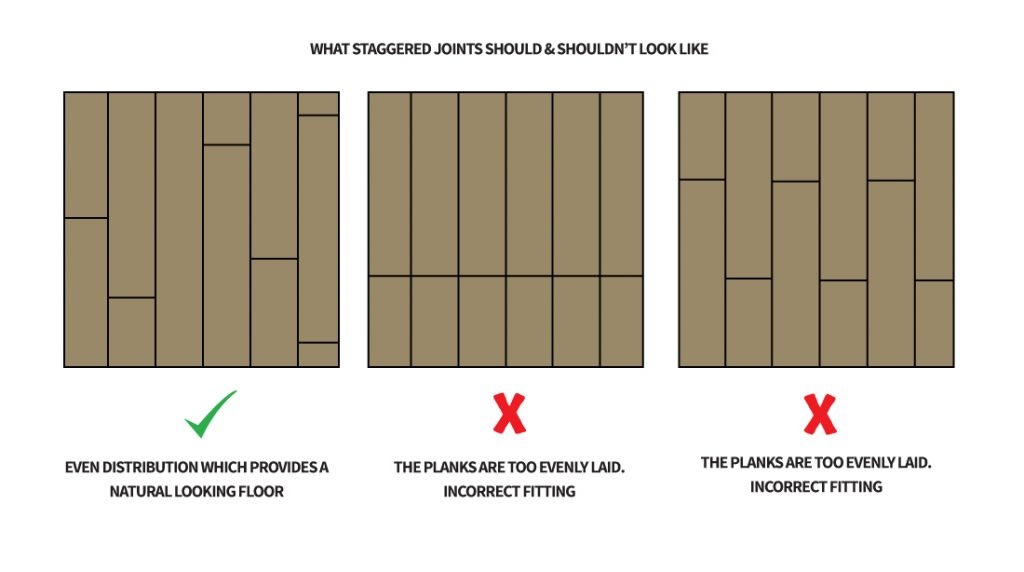

That was the last thought. However the eyeball is the main piece of every new row. Even arrange all the items earlier than putting them in place. Will the joints have random positions? Good. If they appear too uniform, you’ve got an H-match or Step/Lightning problem – this can be solved by following the data below. the back row at 2-3 inches is completely different from any of the first planks in the row but – as long as it’s at least 6 inches.

Additional data to know

- Constraint “H”: When the seams of the main row line up with the seams of the third row, this looks like an H-joint. This pattern does not give your floor a pure look and is retractable. unnecessarily attract the viewer’s eye.

- “Step” or Lightning Cons: The same applies to the tread pattern in flooring. To avoid these, use your cutting boards to start each row differently. Completely different lengths of each cut should allow the seams to fall in random order. If you run out of cuts after only a few rows, keep an eye on the previous two rows and shrink the first plank of the back row so the resulting seams aren’t too tight.

- Rule of thumb: For large 5-inch planks, have a minimum of 6 inches between adjacent row seams. For plank wider than 5 inches, you should be able to increase the minimum to 8-10 inches. However, going beyond 10 inches can get you in trouble while staying away from H-joints.

- Make sure to change your utility blade if it becomes boring. Dull blades can create jagged edges on vinyl planks.

Last, Wallx.net sent you details about the topic “How To Stagger Vinyl Plank Flooring❤️️”.Hope with useful information that the article “How To Stagger Vinyl Plank Flooring” It will help readers to be more interested in “How To Stagger Vinyl Plank Flooring [ ❤️️❤️️ ]”.

Posts “How To Stagger Vinyl Plank Flooring” posted by on 2022-04-09 12:33:05. Thank you for reading the article at wallx.net