How To Cut A Board In Half Thickness

Video How to cut a board to thickness What is the best way to divide these boards evenly (and roughly equally)? What tools do I need to buy? As you requested, I would focus on a hand-tool-only approach but fair warning, even on smaller boards this can be a lot of work and difficult to do correctly. On a 15-inch wide board, it will also pose a great physical challenge – working hard and for a number of hours.Traditional methodThe splitting of an existing plank you’re looking to do here is called re-saw, because you’re re-sawing what was previously sawed in a mill. older woodworking books, it will be quite simple in sketching: you start simply by marking or measuring your cut through between both the long sides and the top of the board, then, holding the work in the opposite direction , start sawing with a suitable saw (a butcheringspecially made for longitudinal sawing).Read more: how to build a wedding arch So the minimum set of tools for this would be:

- ruler and pencil or marker

- table saw, sharpened for cutting

- a deputy to hold the embryo

- one or more small wooden wedges to keep the kerf open

- one or two plane arms to smooth the sawn surface

- scraper and/or sandpaper to smooth the board

Note: the co-pilot must be attached to something quite sturdy and heavy, ideally immovable, so that energy is not wasted moving the table as you have seen. This is one of the reasons for the heavy weight of traditional woodworking benches. The above description of this method makes this sound pretty easy and straightforward but in reality it’s anything, especially on a board of considerable width and/or length.Modern methodThe above could be a significant improvement but unfortunately it requires more work or on your behalf because you need to build the #1 item in the tools list, kerfing plane. Read more about that here on the Unplugged Woodshop page, included with the video. The job of the kerfing plane here is to create a starting groove along all four sides of your board. Sawmillers naturally want to keep track of existing grooves (taking the path with the least amount of resistance), so this makes it much easier to see straight and true through the length of the board. This isn’t a 100% fix, but it helps a lot, so if you’re sawing a lot of things by hand, one of these is well worth the effort.

- kerfing plane

- universal table saw (see note below)

- a deputy to hold the embryo

- one or more small wooden wedges to keep the kerf open

- one or two plane arms to smooth the sawn surface

- scraper and/or sandpaper to smooth the board

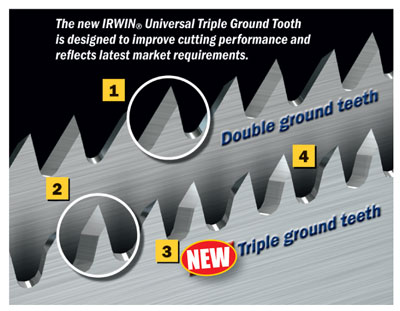

Note: it can be difficult to find a good chainsaw these days and very expensive when you do find a chainsaw. As a result, many woodworkers actually purchase a general purpose board saw with a tooth shape that is different from the traditional western saw for cutting OR cross cutting. An example:

Last, Wallx.net sent you details about the topic “How To Cut A Board In Half Thickness❤️️”.Hope with useful information that the article “How To Cut A Board In Half Thickness” It will help readers to be more interested in “How To Cut A Board In Half Thickness [ ❤️️❤️️ ]”.

Posts “How To Cut A Board In Half Thickness” posted by on 2021-11-15 06:05:18. Thank you for reading the article at wallx.net