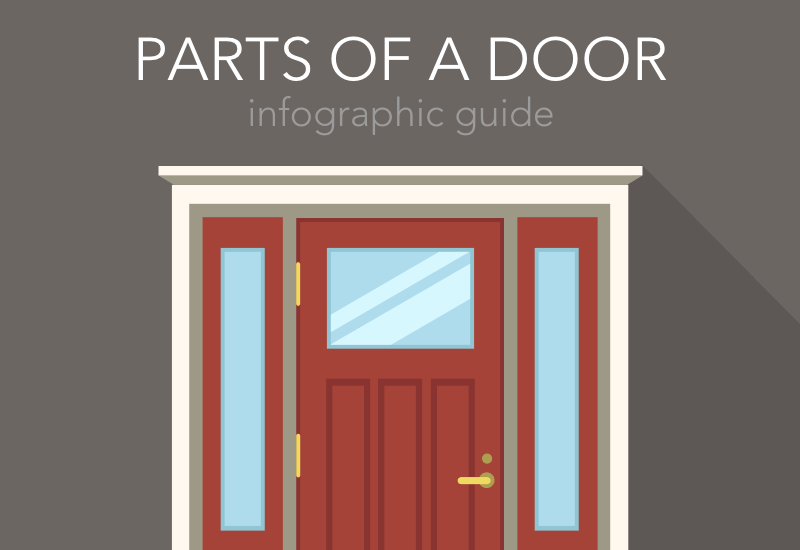

A Quick Guide: Parts of a Door

If you want to make a big impact, replacing your door is one of the simplest things you can do. It’s an easy way to upgrade your home, but before you finish the project or start measuring your door, you should learn the lingo. Let’s take a look at all the different parts of a door and how they all come together.

Door part name

Contents

Frames

The door frame is the entire frame of the door, including the door sill, the guardrail and the top of the door. This is also known as the door shield. Door frames can be made of wood or aluminum, and are made to blend in perfectly with your home. The size of the frame will determine the size of the door to fit.

Sill

The sill is the bottom part of the door frame that rests on the floor.

Jam / jam

Two door spokes are the two sides of the vertical door frame.

The head

The top is the top part of the door frame, running horizontally.

Dashboard

Control panel is the term for the door itself. This is the opening and closing swing.

Astragalus

Read more: Who is William John Garner? If you have a pair of doors in your entryway, the astragalus is the vertical piece that runs between them, from the threshold to the top.

Fixed panel

This is the door panel in a pair of non-closing doors.

Sweep the door

Sweep is a weather-stripped section at the bottom of the door that is weather resistant and forms a buffer between the sill and the door frame. Sweeping doors increases the energy efficiency of your home.

Threshold

A threshold is the transition from the threshold to the floor of the room. A threshold is a decorative element that can be simple or sophisticated, depending on your style.

Horizontal stick

The transom is the horizontal beam that separates the door from the fan light or the window above it.

Strike plate

The backplate is placed on the door guard, where the hole for the latch and latch meet. It is a small metal plate that is screwed into a door latch.

Sidelights

Translucent glass is fixed glass panels that are attached to the sides or sides of the door, outside the frame. These tall narrow windows allow more light into the home.

In or out of the swing

Read more: Who is Scott married to This refers to whether a door pops into or out of a room when opened.

Door handles and hardware

Twist knob

The door handle is a circular mechanism used to open and close the door. Door handles come in a variety of materials, such as antique bronze, brushed bronze, or satin nickel.

Coupling

The hinge is the linking device to rotate the door panel. There are different types of door hinges used on doors including crate hinges, pivot hinges and concealed hinges. This is a type of lock that is installed on the bottom of the door and is foot operated, commonly used on sliding doors.

Key lock

There are so many incredible choices when it comes to entry door locks. There are two types: cylindrical locks, which move the bolt by rotating a cylinder, and multi-point locks, which have multiple locking points but only one handle. Learning door part descriptions is a great way to start your new door project. Doors have a great influence on every day of your life. Replacing a front door will enhance your appeal, save energy and enhance the value of your home. For a visual of where these door components appear, download these door components infographic. Once you’re more familiar with door parts names, it’s easier to talk to contractors and dealers for help choosing the right door for your project. Read more: Marty Caffrey Enjoys single life after divorce from ex-wife, Danielle Staub.

Last, Wallx.net sent you details about the topic “A Quick Guide: Parts of a Door❤️️”.Hope with useful information that the article “A Quick Guide: Parts of a Door” It will help readers to be more interested in “A Quick Guide: Parts of a Door [ ❤️️❤️️ ]”.

Posts “A Quick Guide: Parts of a Door” posted by on 2021-08-21 23:56:05. Thank you for reading the article at wallx.net