Refrigerant Recovery

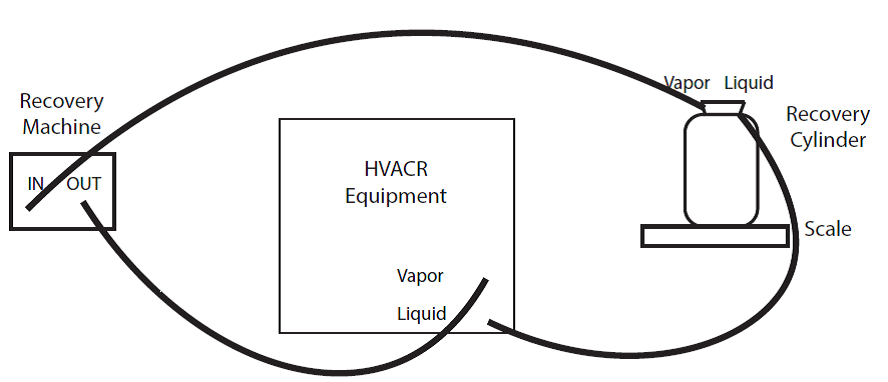

Refrigerant The recuperationI often see new technologies asking how to restore – or even experienced technologies asking how to restore faster, so let’s take a look at both. If you want to connect with a strong culture of HVAC technicians, check out the subscription-based HVAC Know It All app. Read: how to restore freon This all stemmed from some personal trial and error when the manufacturer I worked with recalled, a Schrader went missing. core in the collection service valve (valve king) of all things. This is a possible disaster for an unsuspecting tech, take the cap off and expect a valve core… No fun. So it’s time to install a single valve core in 50 units that operate in critical spaces, and each of them holds between 50 and 100 pounds of R-410A. I ran into a reasonably reproducible situation at hand and I had the chance to try all sorts of things: recovery cylinder size, hose size, hose type, etc. I’ll cover all of those. This is at the end of this article, but we’ve got to start with the basics!How do we recuperate?There are two typical methods of direct recovery and push/pull. You should always familiarize yourself with the equipment you’re working with, but I’ve included a simple diagram of how to connect the necessary equipment as well as “step-by-step” instructions for newer technologies.Straight The recuperationThis is our typical recovery method, and this will be how any restore task will end.1. Start closing all valves (recovery cylinder, recuperator, manifold, hose.) 2. Set up hose as shown in diagram.3. NO/TARE refrigerant scale.4. Open faucet valve, core remover valve or service valve.1. –The below steps will change with your the recuperation machine–5. Set the recovery machine to restore. Open the high wall of the manifold for liquid recovery. PURGE THE HOSE OF THE AIR Loosen and open the hose connecting to the recovery tank until refrigerant is present and then re-tighten. Fully open the steam valve on the recovery cylinder. Read more: how to get rid of bees in the chimney9. Turn on the recovery machine. –The below steps Candlestick it is in Standard arrive most the recuperation machine-ten. It may be necessary to adjust the high side valve of the manifold to throttle the flow of refrigerant into the collector to prevent liquid from slipping.11. When liquid recovery is complete, fully open both the high and low side manifold valves.12. Many recovery machines will shut down when the system reaches vacuum.13. BUY RECOVERY – this can be quite specific – so check the manual if you are unsure.14. Close all valves and restore complete!Push / PullIf the system has 15 pounds or more of refrigerant, this will be your faster choice. The more refrigerant the system holds, the more time you save. Tip: Using the inline viewfinder during push-pull retrieval will allow you to visually determine when liquid flow has stopped.

Last, Wallx.net sent you details about the topic “Refrigerant Recovery❤️️”.Hope with useful information that the article “Refrigerant Recovery” It will help readers to be more interested in “Refrigerant Recovery [ ❤️️❤️️ ]”.

Posts “Refrigerant Recovery” posted by on 2021-10-24 18:16:12. Thank you for reading the article at wallx.net