Import used cars directly from Japan

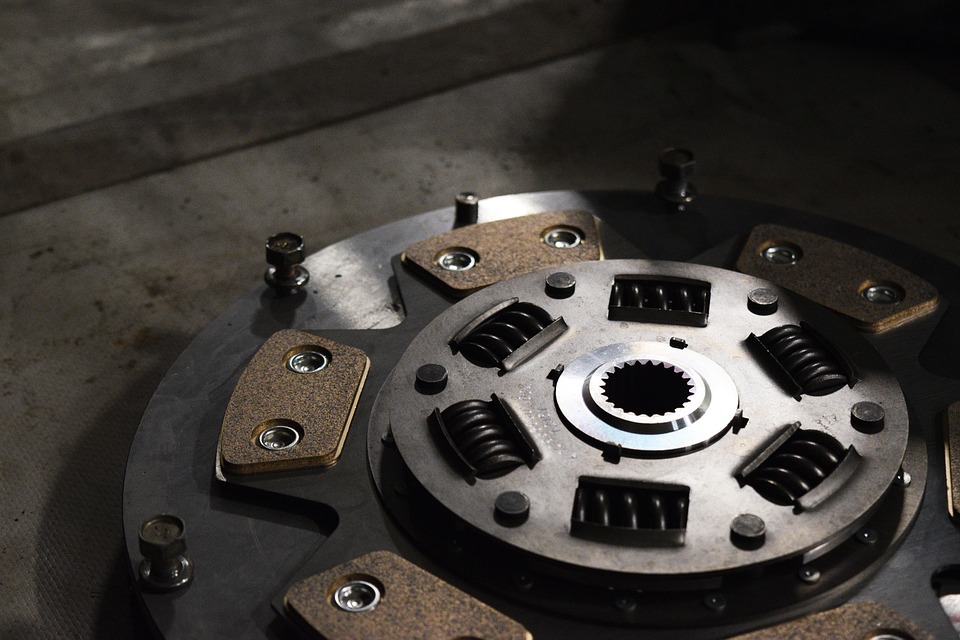

Flywheels in cars have a variety of purposes, including storing energy to keep the crankshaft moving and balancing rotating assemblies. It provides power by smoothly transferring power to the actuator. The clutch assembly helps the engine supply power to the transmission. A large amount of friction is created when the clutch disc is pressed against the flywheel. It clings to the surface and helps the car move down the road. This grip begins to wear off as the lining wears down. Therefore, when replacing pressure discs, people often ask “How to re-surface a flywheel?“So let’s discuss the process! Reading: how to recreate a flywheel

How to resurface flywheel: Complete inspection and resurface

Contents

Every flywheel needs resurfacing at some point. In general, people prefer it when replacing clutches or pressure discs. The mass of the flywheel absorbs the heat generated by the common clutch operation. The clutch generates more heat when it starts to slip or abuse. It can also develop cracks and blisters on the surface of the flywheel. Here are the two main ways to resurface the flywheel.

Cut the flywheel

A brake lathe is required to get started with cutting. This procedure needs to be done carefully as mounting the flywheel on a lathe is not an easy job. The disadvantage of this method is that it leaves uneven areas, because brake lathes ignore hard spots, so people prefer to remove large amounts of metal. When you want to know ‘how to turn a flywheel, you need to know about both cutting and grinding techniques. Read more: How to get your ex-girlfriend to chase you When it comes to hydraulically-linked vehicles, the bearing can have limited movement. It should be understood that the clutch tends to not fully release when too much metal is removed.Flywheel is an essential component of an automobile. (Image source: autmexico) SEE MORE

- Automotive Flywheel: Anatomy of a Working Flywheel

- Double Clutching: Understanding the Mechanism

Flywheel grinding

This is the most preferred technique for flywheel resurfacing. A block grinder is required to perform the task efficiently. Compared with specialized flywheel grinders, head and block grinders require a high set-up time. If not, find another store that has the specific type of equipment for the job. One must make sure to scrape an equal amount of metal on both surfaces. You can measure it with the help of a flywheel depth gauge.

What about dual mass flywheels?

Read more: Steps to get the Double Part Replacement becomes necessary when the dual mass flywheel wears out. In Ford applications, the resurfacing process requires removing the bolts and separating both the primary and secondary flywheels. Ford recommends using new bolts at the time of reassembling the flywheels. The same clutch is not good for solid flywheels. To enhance the powertrain’s torque capability, they manufactured it by keeping the clutch in mind with a larger diameter.

Things To Pay Attention To When Changing Clutch And Flywheel?

When replacing a clutch, one has to replace all the vital components in the system. From the pressure disc, clutch disc and release bearings, everything needs to be replaced. Bearings or pilot bearings also need to be replaced in some vehicles. It works by aligning the clutch disc with the flywheel. It will lead to quick clutch and bearing wear after wear. A serious consequence includes clutch separation problems. However, index positioning becomes superior in the case of an externally balanced engine. The technique here is to mark the position before removing and reinstalling the flywheel to the crank. This pro tip will help maintain correct engine balance. Mark the flywheel when you are not sure if the engine is internally or externally balanced. It will help you install it in the exact same location as it was originally.

Final Notes

Last, Wallx.net sent you details about the topic “Import used cars directly from Japan❤️️”.Hope with useful information that the article “Import used cars directly from Japan” It will help readers to be more interested in “Import used cars directly from Japan [ ❤️️❤️️ ]”.

Posts “Import used cars directly from Japan” posted by on 2021-08-20 21:02:08. Thank you for reading the article at wallx.net