How To Remove Powder Coat From Wheels

If you’ve ever tried to strip an object that has been powder coated before, you know it can be stubborn. Durability is a major benefit of powder coating but also makes it a pain to remove, leaving yourself to wonder how to remove powder coating easily.Powder coating can be removed using chemical strippers such as Benco B17, heat, abrasives (sandblasting with new media), or lasers. Each method has its advantages and disadvantages that you’ll need to consider when choosing which to use.Reading: how to remove powder coat from wheelsIn this article, we’ll discuss the main methods that you can use to remove powder coating. As well as the pros and cons for each, safety precautions you should take, and what supplies you’ll need for each method.

Methods How To Remove Powder Coating

Contents

Powder coating uses an electrostatic charge to cover every inch of an object. It’s so effective that it can be hard to remove.There are four main ways to remove powder coating, which will be covered in-depth in this article:

- Chemical strippers

- Heat or thermal removal

- Abrasive blasting

- Laser removal

Why Would You Need To Remove Powder Coating?

Fixing mistakes. If you’ve just started powder coating yourself, you’re bound to make errors. On your first few tries, your coating might not come out as good as you’d hope for. So you’ll want to be able to remove the powder coating to try again.Refinishing. If you have an old piece of metal, you might just want to refinish or update it to keep it looking shiny and new.Cleaning. After you’re done powder coating, you’ll need to strip your cleaning hangers and racks or they will just keep building up with thicker and thicker coats each time you complete another job.

Chemical Strippers

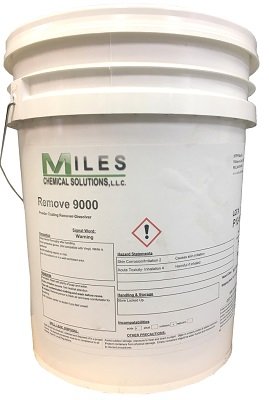

When it comes to removing powder stripping, your first option is to use a chemical stripper.A great powder coat chemical stripper you may not be aware of is Miles Remove 9000 you can get more details here (dipping application) or Miles Remove 9001 a gel version (applied with a bristle brush). Both are great for powder coat removal from as quick as 15 minutes – 2 hours or overnight depending on the type of coating being removed. It is Eco-friendly and excellent for job re-work as it can be re-used and even diluted when heated, saving you money!Powder Coat RemovalThe best part about Miles Chemical stripper remove 8659, 8660, 9000 and 9001 is they are non-toxic, non-D.O.T. regulated, low odor, and noncaustic (won’t burn your skin.) If you are looking for innovative powder coat removal/stripper that will work with a variety of applications including stubborn rims and aluminum wheels check out the Miles 8659 Gel or Miles 8660 liquid here. The 8660 can be diluted with water, to save even more, when in heated tanks and are a great alternative to the caustic Benco products which are now hard to get.All of the Miles products can also be shipped to residential addresses.

Chemical Stripper Pros

Using chemicals to remove powder coating will leave you with a uniform surface after you’ve removed the coating. Some other methods like sandblasting can scratch or remove tiny pieces of metal. If you’re not re-coating the surface you’ll probably want it to be smooth and shiny without scratches.Chemical strippers are cheap and available in small quantities. They’re great for a one-time job or for someone who doesn’t need to remove powder coating very often. They are also available in bulk for more frequent and larger jobs.

Chemical Stripper Cons

Chemicals used to remove powder coating can be really bad for the environment and have strict requirements on how to dispose of them. Also some chemical strippers are more dangerous to work with compared to others.Chemical strippers also don’t leave a profile for a new coating of paint to stick to. If you’re planning to re-coat the metal you’re stripping, you might want to sandblast it instead. The scratches and marks from the adhesive make it easier for many types of paint to stick to metal.

How To Work With A Chemical Stripper Safety

Working with chemicals that are capable of melting powder coating off of metal can be dangerous. Even a small drop will burn your skin, and getting it in your eyes can cause permanent damage.Take the safety warnings seriously and wear the proper equipment.You’ll want to wear thick rubber gloves, ideally elbow-length. It’s best to get a cheap pair and immediately throw them away when you’re done, rather than trying to clean them. Otherwise, you risk getting the chemical on your skin after you’ve taken your gloves off.

Using A Chemical Stripper – Steps To Follow

1. Do a spot test firstRead more: Can You Repair an Expandable Garden Hose?You’ll want to start off by spot testing your item with your stripper to make sure it will work. Apply a small amount of the stripper by following the recommended instructions. Then try to scrape off the powder coat with a scraper.If the coating comes off fairly easily, you can go ahead and apply the stripper to the entire object. If the coating is still really stuck on, you can spot test another area and give it more time. Or you might need to get a stronger product if it still doesn’t work.2. Apply your stripper Coat the entire part in the chemical stripper. Let it sit for the same amount of time that you used for your successful spot test.3. Scrape the coating off After enough time has elapsed, it’s time to clean the powder coating and solvent off. You can use a bladed paint scraper or a chipping brush for this step to start with.Once most of the coating has come off, you can go over the metal again with steel wool or an abrasive pad to get any remaining coating off.If you’re struggling to get all of the coatings off, you might need to re-apply the chemical stripper and wait again.4. Wash your partRinse your stripped part off with water and detergent to remove all remaining traces of coating and chemicals. Make sure to dispose of the removed coating carefully.

Stronger Chemical Strippers For Larger Jobs

Most of what I discussed above regarding chemical strippers is aimed more at DIYers and hobbyists.If you need to strip powder coating off large numbers of pieces or you just want to do it faster and more efficiently, I’d recommend a stripper that’s designed for more industrial applications such as Benco B-17 or 1010P.

Benco B-17 Industrial Liquid Stripper

Can strip about 3mm of powder coating in less than 20 minutes. It contains stronger and faster-acting chemicals like methanol chloride, phenol, and hydrofluoric acid that aren’t found in retail strippers.1010P is less powerful than B-17, but will still work better than anything you can buy at your local hardware store.Be aware that these industrial chemicals can normally only be ordered in larger quantities – such as 5 gallons, 30 gallons or 55-gallon drums. So they’re really only a good solution if you own a shop and will be stripping powder coating on a regular basis.You will also need a container to do your stripping in unless you intend to strip items in the drum it was shipped in.You’ll need to be extra safe when handling industrial strength chemical strippers. They can remove powder coating faster than retail strippers, but that means they can do real damage to your skin if not handled correctly too.Benco B-17 stripper costs about $200 for 5 gallons. Although many companies will no longer ship it to residential addresses since it’s considered a hazardous product.

Method Two – Heat or Thermal Removal

Heat Removal Pros

Using a heating system is fast and efficient. It’s great for doing large volumes of stripping.When done correctly, thermal processes release nearly no contaminants back into the environment, unlike chemical strippers.

Heat Removal Cons

The equipment used for thermal stripping consumes a lot of energy and can be expensive to buy. They can easily cost thousands of dollars.Some heat removal methods need a wash phase to remove burnt powder after they’ve been processed.Whether you use electricity or natural to power your ovens, they will result in a high utility bill.The high temperatures used to mean you risk altering the shape of the underlying metal. Heat removal also doesn’t leave a profile for the new paint to adhere to, similar to chemical stripping.

Method Three – Abrasive Blasting

Abrasive blasting (sometimes called mechanical removal) uses an abrasive media like sand which gets shot at the powder coating surface at high speeds. This strips the coating off the metal’s surface.To use this method, you’ll need a sandblast cabinet. Sandblast cabinets come in two main types, pressure and suction. For removing powder coating it’s best to use a pressure sandblast cabinet. It’s better at removing the stubborn powder coating.Read more: how to draw a smile step by stepIf your object is too large to fit in a sandblast cabinet, you’ll need to set up a sandblast room or tent.You can’t simply use abrasive blasting in your garage. The abrasive media will go flying beyond the object you’re stripping and damage anything else in its path.

Abrasive Mediums

- Sand

- Water

- CO2 pellets

- Garnet

- Dry ice

- Slag

- Plastic Media

Picking the right media affects the profile left on the metal’s surface, as well as how fast it works. The more aggressive a media you choose, the faster it will clean but it will also leave the roughest surface on the metal.

Abrasive Blasting Pros

Using abrasives is fairly cheap if you’re doing it on any kind of scale. The equipment is much less expensive than using ovens. It can be good for smaller shops between what a DIYer needs and what a large-scale industrial operation would use.Abrasives are also a portable option. You can use a small sandblasting cabinet or pot to remove powder coating in the field.Using abrasives leaves a surface profile, which makes it easier to apply some paints and coatings.

Abrasive Blasting Cons

Abrasives can be a bit slower of a stripping method. It usually takes about 30 seconds for each square inch of powder coating that you want to strip away.Each part you want to strip has to be blasted individually, which means higher labor costs.Parts that have irregular shapes can be difficult to blast and can trap abrasives, potentially causing problems with future coatings if not fully removed.Abrasives are good for steel and harder metals, but they can erode softer metals like aluminum.

Method Four – Laser Removal

Laser Removal Pros

Lasers are very precise and can strip powder from a small area, but they can be used for large surfaces too.They can be used on nearly any material since they don’t alter the substrate underneath the powder coating. The heat of the laser doesn’t touch the actual surface of the metal while stripping, which makes it perfect for aluminum.Lasers have little to no impact on the environment.

Laser Removal Cons

As you’d imagine, lasers are pretty cutting-edge technology and they can be very costly to buy. For that reason, lasers are only really practical for stripping in a production environment.Like all of the other methods except abrasives, laser removal doesn’t leave a profile on the metal’s surface, meaning extra steps might be needed before re-applying paint or another powder coating.

Which Powder Coating Removal Method Should You Use?

Conclusion

Removing powder coating yourself can be a lot of work.To figure out what method you’ll use to remove powder coating, you should consider a few things like the volume of powder coating removal you need to do, as well as the type of metal you’ll be stripping.If you only need to remove powder coating once or twice a year, it’s probably easiest to just buy some commercially available chemical stripper.For small shops or a hobbyist who frequently needs to remove powder coating, using abrasives with a sandblast cabinet can be a good solution.Bake off ovens, blast rooms, and large chemical stripping tanks make sense only on larger (industrial) scales for large batches of work.Deciding the right method for removing powder coating normally involves balancing out the time it will take you compared to the cost investment required. Don’t forget to Check Out The Eco Friendly Powder Coating HereRead more: how to play say it aint so

Last, Wallx.net sent you details about the topic “How To Remove Powder Coat From Wheels❤️️”.Hope with useful information that the article “How To Remove Powder Coat From Wheels” It will help readers to be more interested in “How To Remove Powder Coat From Wheels [ ❤️️❤️️ ]”.

Posts “How To Remove Powder Coat From Wheels” posted by on 2021-11-06 04:25:29. Thank you for reading the article at wallx.net