How To Release A Suspension Or Steering Ball Joint

You must remove the ball joint to make other repairs

Contents

The ball joint is used to act as a universal swivel connecting the upper or lower control arms to the crankshaft, which is where the bearing and wheel are supported. This joint is also responsible for allowing the steering to operate as it is the bottom part of the shaft for the shaft to rotate. Constructed of a metal housing with a spherical metal ball, the ball joint is designed with a threaded stud attached at one end. This ball joint is designed with a lightly taper hole that locks into a taper hole for strength measurement when attaching the ball connection to the spindle. The ball is trapped inside the shell with enough space to move freely without playing. Grease used to lubricate joints may have a Zerk coupling used to fill the joint at regular service intervals. Most cars today have unusable couplings that are equipped with enough grease to prolong the life of the ball joint. undone means removing the nut from the joint and applying pressure while hitting the swingarm’s spindle or control end with a hammer. Some ball joints have a cotter pin that is used as a safety device to keep the nut from unscrewing and the coupling from being undone. Other designs have self-locking nuts without cotter pins. The hardest part of removing any ball joint is disconnecting the taper joint at the end of the joint. Some ball joints are made into lower or upper control arms while in other applications the joint can be disassembled separately. You should align the vehicle after replacing the ball joint. Read: how to remove ball joint

What’s wrong?

When the ball joint wears out due to normal use and movement of the steering and suspension components, the joint becomes overworked causing problems such as making the steering wheel vibrate while driving and creating crackling sound when the vehicle is being driven and passes the collision. Ball joint wear can also contribute to uneven tire wear.

How much it costs?

An armless ball joint will cost between $15.00 and $26.00 (US) each on Amazon. If the ball joint is not serviced separately and is included with the control arm, you can expect to pay between $46.00 and $92.00 per hand. Labor to replace a ball joint with a handle will range from $120.00 to $180.00 depending on the manufacturer. To manually replace the ball joint will run the same for labor.

Start

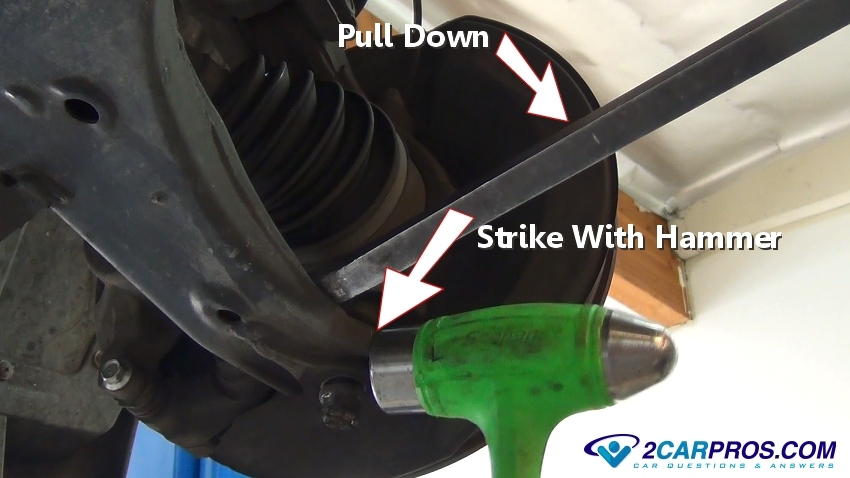

The vehicle must be raised off the ground and supported on a support. You may need to remove the wheel to access the ball joint more freely. There are two types of ball joints, one facing down while the other facing upwards. Each is similar and will require a different position of the break bar to undo. We will cover both styles in the tutorial. All ball joint connections are a coupler that must be released to undo. This guide is for strut mounts with coil springs encased in struts. If this is to be done on a direct-spring suspension, the bottom handle should be supported using a jack and then slowly lowered when the ball joint has been undone. Live spring suspension is a system with springs pressed into the bottom control arm. This spring is very strong, so care should be taken when handling this spring.1. Removing the cotter pin The cotter pin is used to preserve the connection between the ball joint and the control arm in the event of a loose nut. The nut in the picture below is called a castle nut which has 6 positions where the cotter pin can keep the nut moving. Use a pair of side cutters (dyke) to remove the cotter pin from the castle nut, this will allow the nut to be removed. 2. Loosening the Castle Nut Use a 19mm to 22mm wrench or socket to loosen the nut by turning it counterclockwise. These nuts can be quite tight so make sure the socket or wrench is perpendicular to the nut before applying force to avoid rounding and damage to the nut. Do not completely remove the nut, leave it on the nail for about three turns to protect the stud threads when unscrewing.

Have any questions?

If you have any ball-related questions, please visit our forum. If you need auto repair advice, ask our community of mechanics who are happy to help and it’s always 100% free. We hope you enjoyed this tutorial and video. We are creating a complete set of auto repair manuals. Please subscribe to our 2CarPros YouTube channel and check back often for new videos being uploaded almost every day. Read more: how to get motocross sponsorship

Last, Wallx.net sent you details about the topic “How To Release A Suspension Or Steering Ball Joint❤️️”.Hope with useful information that the article “How To Release A Suspension Or Steering Ball Joint” It will help readers to be more interested in “How To Release A Suspension Or Steering Ball Joint [ ❤️️❤️️ ]”.

Posts “How To Release A Suspension Or Steering Ball Joint” posted by on 2021-11-06 12:05:13. Thank you for reading the article at wallx.net