How To Print Helmets That Fit Me

One of many coolest issues that you may make with a 3D printer is a helmet that you may truly put on. The very best half is that it doesn’t matter what measurement 3D printer you might have, you may nonetheless print a full-sized helmet.So how do you 3D print a helmet? In case your 3D printer is just too small to print the helmet in a single piece, then you may cut up it into separate elements and be part of them up later.Reading: How to print helmets that fit meOn this article, I’ll share with you the issues that I’ve realized in regards to the course of. This is only one instance however you would do that to each single half resembling shoulders, biceps, forearms, chest, again, abs, cod, thighs, shins, boots and extra.

Discovering a 3D Mannequin of the Helmet

Contents

The very first thing that you’ll want in order for you to 3D print a helmet is the 3D mannequin. Simply search on Thingiverse.com, and if it’s a widely known helmet then someone has most likely already made a mannequin of it and posted it there. When you can’t discover something on Thingiverse, then strive simply looking out the net for it. Generally individuals submit their 3D fashions on different web sites.For instance, you would search one thing like “so-and-so helmet STL file,” or “so-and-so helmet 3d model for 3D printing.” In case you don’t know, an STL file is simply the kind of file that lots of objects for 3D printing are saved as. If there’s a 3D mannequin on the market then searches like that ought to give you the chance to find it. Generally individuals will design objects for printing after which promote the recordsdata, so it won’t be free, however a minimum of it’s already designed.When you’ve searched Thingiverse and the remainder of the web and nonetheless haven’t discovered a 3D mannequin to your helmet, then you might have a couple of choices of what to do. You’ll be able to both design a 3D mannequin your self, or strive to discover another person to do it.The simplest approach would most likely be to rent somebody to design the helmet for you, except you know the way to make 3D fashions your self. Web sites like Fiverr.com have lots of people you may select from who can design the mannequin for you. Costs can vary anyplace from $5 to lots of of {dollars}, however normally for one thing like a 3D mannequin of a helmet it shouldn’t price that a lot.If you would like to strive designing the helmet your self, there are totally different 3D modeling applications that you would use. One good one that’s extremely popular known as Blender. I’ve tried to use it earlier than, and it’s fairly troublesome to find out how to use, however when you get used to it it may be a really efficient software. Additionally, it’s utterly free, and there are lots of tutorials on-line on how to use it. When you’ve got the time and are keen to study Blender, it may be an excellent choice.Then there are applications that you should buy, like Simplify3D, AutoCAD, and Solidworks. There are numerous extra, however these are those I hear individuals use essentially the most. I personally haven’t used any of them, so I like to recommend you look them up to see which one is perhaps greatest for you.

Ideas for Scaling a Helmet to Fit Your Head

If you’re uncertain in regards to the scale, please don’t print the total piece from the begining. There’s a approach to save filament and check issues out with minimal price and time.Helmets want to be sized larger particularly in case you are going to set up hinges or servo motors inside. Our fashions are principally scaled for a 6 foot tall 3D avatar however as a result of we adopted the proportions of a CGI mannequin to keep away from a bubble head look, typically, you may enhance the size by 5 ~ 10%. Some individuals scan their head into an stl file, after which fit the helmet on the digital head. The check will get you the fitting measurement so that your helmet will fit completely.When you scale the helmet to your measurement, you should use that helmet as a information for future helmets. Merely open up one other helmet that you want to scale and put it subsequent to the “perfect fitting” helmet. Use the “perfect fitting” helmet as a information to scale up/down the opposite helmet to the identical measurement.Right here is an instance from Do3D. The software program on this video is Autodesk Netfabb, however virtually each software program has a slicing software.

Splitting the Helmet

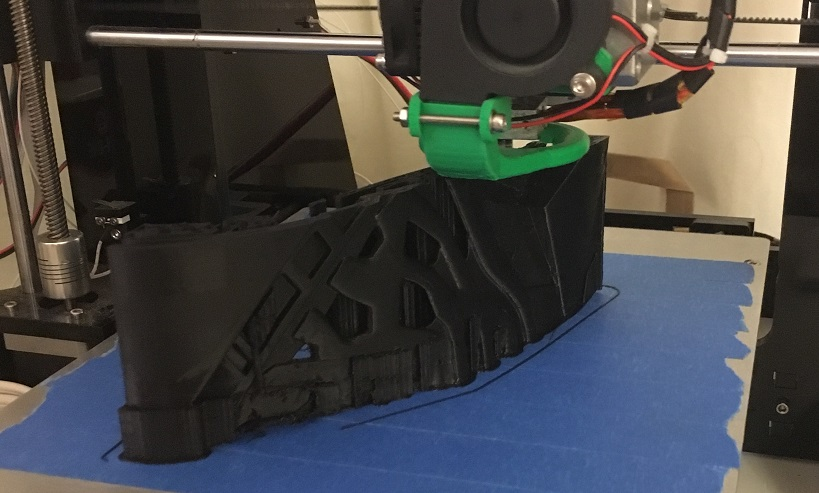

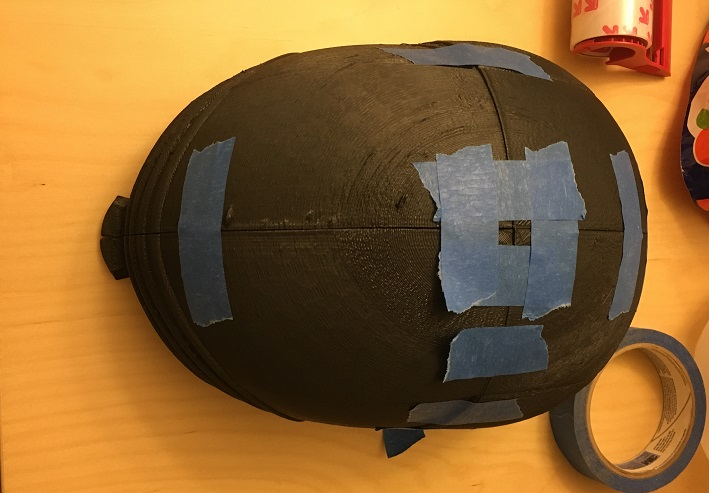

When you’ve got a small to medium sized 3D printer, then you definately most likely received’t give you the chance to print a full-sized helmet in a single piece. You’ll be able to flip to a web based 3D printing service firm like FacFox and customized one with our industrial 3D printer.Read more: Time for New Nipple Jewelry? | Top Q&AWhen you’ve got a 3D printer large enough to print your helmet in a single piece, then that will prevent the difficulty of getting to assemble a number of items afterward. Nonetheless, it might probably take a really very long time to print one thing as massive as a helmet unexpectedly. I’m speaking a number of days for some helmets. For a print that lengthy, if only one factor goes improper, then the entire thing might be ruined. However with FacFox’s industrial 3D printer, issues as giant as helmets might be printed in in the future and post-processed in one other day.So even you probably have the capability to print a helmet in a single piece, you would possibly nonetheless need to cut up it. Some helmets that you discover on-line may have an entire model together with a model that has already been cut up into elements. If you will discover one like that then that’s nice, however there can nonetheless be some points.If it was cut up alongside easy traces, just like the one I printed, then it may be arduous to match the items up precisely proper. This could lead to different items being misaligned, and if it’s unhealthy sufficient then you definately might need to begin over. You’ll be able to repair this by both lining all the things up as fastidiously as you may, or by including what’s referred to as registration marks.Registration marks might be bumps, pegs, or every other formed protrusions that stick out of 1 aspect of piece and line up with holes on the opposite piece. Having these will make it straightforward to fit the 2 items collectively so that they line up completely. In case your helmet has already been cut up they usually didn’t put any registration marks, then it could fairly arduous to put them in your self. The easiest way to add them is to do it if you cut up the helmet.It’s truly not very troublesome to cut up a 3D mannequin by your self. There are a number of applications you should use to do it, however the one I exploit is Meshmixer. It’s a free software program that helps you to edit 3D fashions in many alternative methods, together with splitting and including registration marks. I discovered an excellent video that explains step-by-step how to do that, so I’ll hyperlink it right here. It’s most likely simpler for you to watch it than if I strive to clarify it.In case your helmet has any protrusions, like horns or spikes, then it is perhaps higher to slice these off and print them individually. It might probably trigger points with needing help afterward if you print, and that can restrict your choices for a way you orient the piece.

Print Orientation and Helps

Becoming a member of the Elements

Sanding

To organize your helmet for portray, you might have to easy out the floor as a lot as you may to do away with the layer traces. You are able to do this by both sanding the floor down, or by utilizing a primer paint that is particularly designed to fill gaps. I haven’t used the filler primer myself, however I’ve heard that it really works effectively. I’m unsure if it could fill in small particulars although, so it won’t be the most suitable choice for some helmets.In my case I sanded the complete helmet with a rough sandpaper till it was principally easy, after which I went over it once more with a finer grit sandpaper. At first I did it by hand, however once I realized how gradual the progress was going, I switched to an oscillating Dremel software to velocity issues up.One tip that I’ve is that it’s best to ceaselessly clear out your sandpaper, as a result of it might probably get clogged with plastic in a short time. Additionally, I feel that the sanding course of would have gone a lot quicker if I had modified out the sandpaper extra typically. As an alternative I solely modified it out a couple of occasions throughout the entire course of. It most likely misplaced most of it’s sanding functionality lengthy earlier than I ended utilizing it. So save your self lots of time and solely use the sandpaper whereas it’s contemporary. As quickly because it stops working as effectively, swap it out.Watch out not to sand an excessive amount of, as a result of usually 3D prints don’t have very thick floor partitions, except you printed it utterly strong. In case your wall thickness is barely a millimeter or two, then be very cautious to solely sand away simply sufficient materials so that it turns into easy. When you go any deeper you’ll undergo to the infill materials, and your print can be ruined.If you would like your helmet to have a brilliant easy end, then it’s best to sand down to round a minimum of 360 grit. Regular primer and paint received’t disguise many imperfections, so the smoother you may sand down the floor of your helmet, the smoother it’s going to end up. For my helmet I solely went to 240 grit, as a result of I knew that I’d be including texture to it later, so a easy end wasn’t mandatory.

Priming and Portray

Upon getting your helmet as easy as you need it, you can begin the portray course of. In my view, as a result of it’s very troublesome to get something to stick to PLA, it’s greatest to all the time use a primer earlier than you paint. I do know that some individuals skip this step, however I feel that it’ll offer you a a lot longer-lasting paint job.For my helmet I simply used a standard grey primer. I gave it one coat, let it sit for an hour, after which gave it one other coat. Then I let it dry for a few week. Which may seem to be too lengthy of a time to wait, however within the nice print of the primer can it says that for plastic, most adhesion happens after 5-7 days. So I made a decision to keep on the protected aspect and wait every week earlier than I continued.For a easy end in your helmet, you may apply paint after the primer, however in my case I wished my helmet to have some texture. I used a stone texture spray paint after the primer and let that dry earlier than I painted it.My helmet was fairly easy to paint as a result of most of it’s all black, with some silver elements that I hand-painted later. When you’ve got areas that want to be totally different colours, then you should use masking tape to part them off. Be very thorough if you masks areas off, as a result of any errors will imply you’ll have to repair it later. The higher a job you do taping issues off, the higher it ought to end up the primary time.After I had the entire thing painted, I went over it with a matte clear coat spray. In addition they make medium gloss or excessive gloss clear coats in order for you that type of end. I feel that a transparent coat is a good suggestion as a result of it’ll assist to defend the paint, so that any scratches or bumps have much less of an opportunity of damaging the precise paint.

Ending

Upon getting your helmet painted, you may add the ending touches. This may be issues like a visor, a material display screen on the within, straps, or padding. I put padding inside my helmet to give it a comfortable fit and maintain it from wobbling round on my head. I additionally glued a skinny black sock materials across the eye and face holes so that individuals received’t give you the chance to see into my helmet. When you do that, I like to recommend you utilize a really skinny materials so that you may nonetheless see out, or stretch it so that it turns into extra see-through.

Conclusion

I hope that this text helps you as you strive to 3D print your individual helmet. It may be an extended and arduous course of to go from nothing to a completed product, however I feel it’s utterly price it. Hopefully you realized a bit from my errors and suggestions, and I want you luck together with your tasks.Read more: how to prevent frost heave in concrete slabs

Last, Wallx.net sent you details about the topic “How To Print Helmets That Fit Me❤️️”.Hope with useful information that the article “How To Print Helmets That Fit Me” It will help readers to be more interested in “How To Print Helmets That Fit Me [ ❤️️❤️️ ]”.

Posts “How To Print Helmets That Fit Me” posted by on 2022-05-03 22:45:02. Thank you for reading the article at wallx.net