How To Make Gold On Led Strip Lights

LED string lights are fast becoming a popular choice for lighting commercial, residential and industrial spaces. This is because they are efficient, easy to install, and require little maintenance. You can customize LED strips to any shape and size so you can use them to light up almost any space.Read more: how to make gold on LED string lights Read more: Zomboid how to make lights Source: Shutterstock

What is LED strip light?

Contents

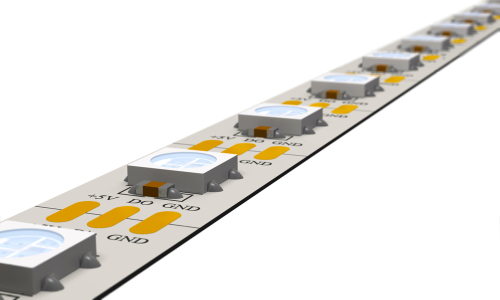

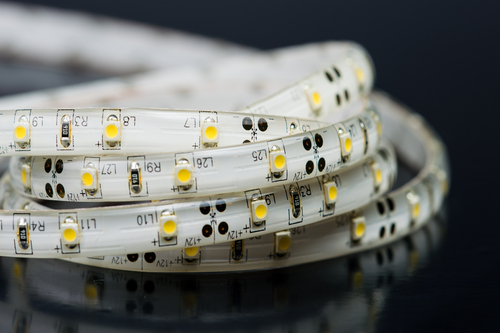

A light strip LED is a flexible circuit board that has a series of SMD (surface mount) LEDs (light emitting diodes) and a resistor attached to it. LED strip lights are also known as ribbon lights or ribbon lights. They can be made by both analog and digital LEDs and can emit white light as well as light of any other color. LED strip lights are 80% more efficient than normal bulbs. They give off very little heat which is easily dissipated and they are mercury free. They seem very small on their own, but together they can emit an enormous amount of light just right to brighten up any space.

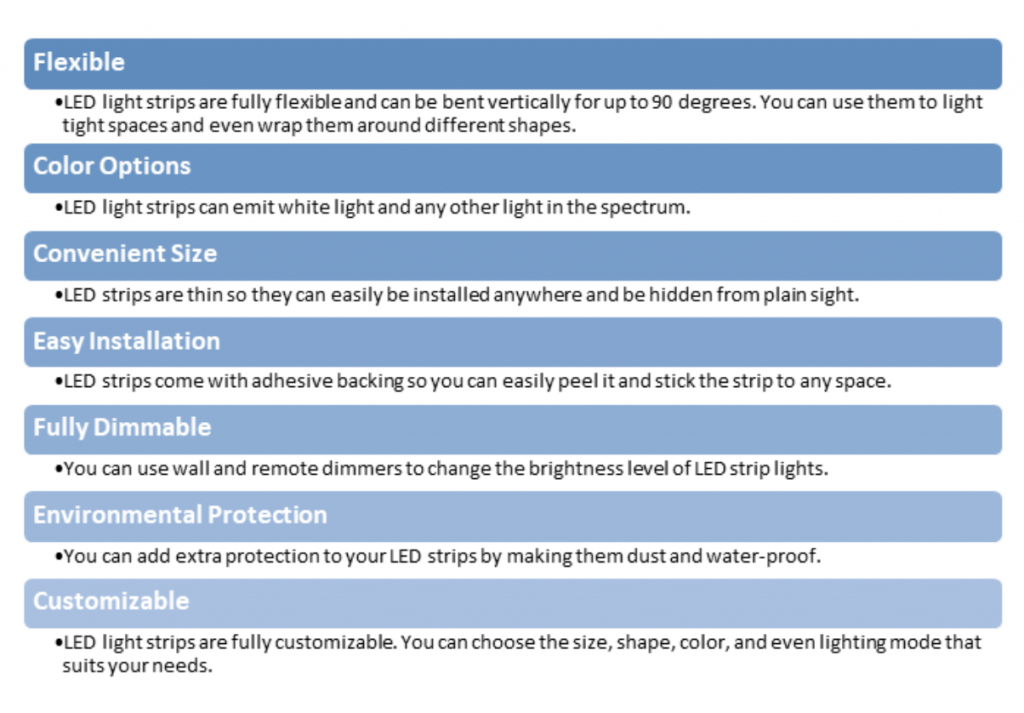

Features of LED strip lights

Here is a list of features that make LED strip the ideal choice for lighting your home, office, vehicle and more:

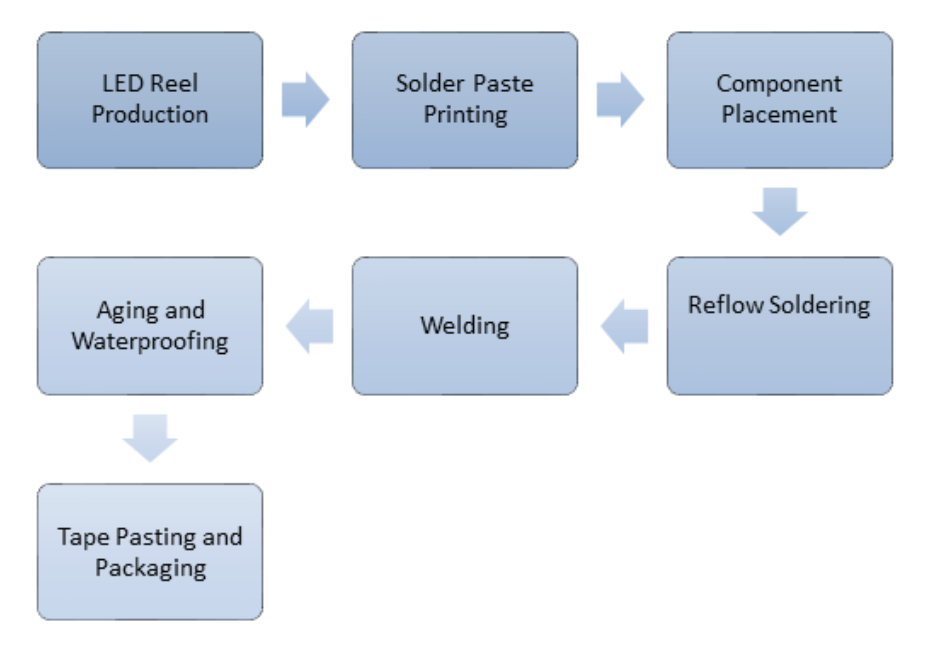

LED strip light manufacturing process

As LED strips become more popular, their manufacturing process also becomes more streamlined. LED strips are basically printed circuit boards (PCBs) soldered together to the right length. PCBs use a process called Surface Mount Technology (SMT) Assembly Process to mount LEDs and other components onto the board. Using the PCBA process, we can truly customize your LEDs at the PCB level to fit your specific lighting needs. We also perform quality control checks at the end of each step to ensure our products are up to standard. Here’s how the process works:

Step 1: Production of LED coil

The first step in LED strip manufacturing is placing the LEDs and other components together on a roll. Placing all components including LEDs and resistors on a single coil ensures effective gluing on the board later in the process. At Elstar, we use a sophisticated device to fix the LED panels to the reel. We arrange these wafers in the correct order, ready to be glued in the next step of the process. The panels are fixed using wire bonding. We use 99.9999% pure industrial gold to ensure the longevity of the connection. The spectrometer automatically classifies LEDs based on current, voltage, and color. This helps it to connect LEDs of the same specifications together on a single coil. When the LED rolls or strips are ready, we seal them in a vacuum bag to protect them from dust and moisture. We also incorporate light colors to maintain light consistency. Each reel also undergoes manual microscopic inspection to ensure proper placement of the reels.

Step 2: Print Solder Paste

The next step in LED strip manufacturing is to get the PCB ready to be glued onto the LED components. This is done using a process called solder paste stenciling. The paste is a gray substance that contains small metal pellets called solder. The balls are made mainly of steel with traces of silver and copper. This adhesive layer is glued on the PCB at the locations where the components need to be attached.

Step 3: Component location

After applying solder, the SMT machine will then place the components in their intended locations on the PCB. The LEDs on the coil are placed on the PCB using a robotic device that places each component exactly in its place. This process was previously done manually but that has led to quality control issues. Since then, SMT machines have been equipped with specialized equipment to ensure the correct placement of components.

Step 4: Solder

Now that the solder and components are placed on the PCB, you need to make sure they are still there. This is done by placing the PCB through a process called Reflow Soldering. The PCB board, together with the glued components, is placed on a conveyor belt. This conveyor belt feeds the board back into the kiln. This oven is similar to a commercial pizza oven. It consists of a series of heaters that gradually heat the PCB until it reaches a temperature of 250 degrees Celsius (480 degrees Fahrenheit).

Step 4: Solder

The LEDs come out of the bright light in the form of a 50 cm strip. They are then soldered together by connecting one strip to the other. Strips are now connected together by advanced machine like robotic welding arm of any length you want, so welding robot cost is also needed for reliable LED manufacturers to ensure strip quality assurance. Test to make sure the strips work as promised. The light test confirms that the strips do not have any loose circuits. Other electrical and optical tests are performed to ensure the LED strips meet all of our standards and all your requirements.

Step 5: Anti-aging and waterproof

Welded LED strips are put through a process called aging to test their performance. The LED strips are left on for 12 consecutive hours to see if they work continuously. This test helps us check the quality of the LED strips and fix any problems.

Step 6: Paste and pack the tape

Once the LED strips pass all the quality checks, we apply 3M tape to the back of them. This makes it easy for customers to install LED strips wherever they want. We use quality 3M tape that adheres to any surface with ease. The final step is to pack the LED strips and deliver them to you. Quality check: Our final quality check is a random check of the LED strips that are ready for packing. This helps us maintain our high quality standards.

Factors affecting the quality of LED strip lights

LED strips are only as good as their quality. The problem is that you can’t really know the quality of a strip until you actually start using it. This is why it is important to purchase LEDs from a reliable LED strip manufacturer. Here are some factors that affect the quality of LED strip:

-

Quality of copper wire in PCB

Copper wire is used in the PCB board to ensure that current flows seamlessly to all components installed on it. The quality of the copper wire used can affect the performance of the LED strip. If the copper wire is too thin, current will not be able to pass through it and your LED strip may not work or suffer a voltage drop. Low-quality copper can also interfere with current flow and affect how the LED strip works.

-

Quality of Phosphor in LEDs

Phosphorus is used in LEDs to increase the fluorescence of the light. It is essential to produce pure, bright and unpolluted white light. Poor quality phosphors can make your LEDs look dimmer. It can also make the color not pure. It is important to note that phosphor degrades over time and with use. But good quality phosphor retains its structure longer, helping your LED strips shine for years. Otherwise, the LED strip will not work. So choosing the right equipment like pick & place robot is also very important. Another mistake is to combine different sized LEDs on a single strip. This reduces banding efficiency and accelerates phosphor degradation. Different LEDs are often combined to make the LED strip look brighter at a lower cost. However, these LED strips don’t last long and cost you more. LED strip with good quality LEDs, resistors and PCB stands out from the rest. Not only do they work better, they last longer. Quality indoor LEDs have color consistency issues and die sooner. Damaged resistors and PCBs affect current flow and can cause LED strips to heat up.

Inference

A good quality LED strip can be a one-off and complete solution to your lighting needs. It’s always a good idea to do your research before making a buying decision. If you want to know more about our LED strips and LED strip profiles or have any other questions, feel free to comment. Our aim is to provide high quality LED lighting solutions that will extend your life for many years! Read more: how to use an electric smoker memphis pit boss

Last, Wallx.net sent you details about the topic “How To Make Gold On Led Strip Lights❤️️”.Hope with useful information that the article “How To Make Gold On Led Strip Lights” It will help readers to be more interested in “How To Make Gold On Led Strip Lights [ ❤️️❤️️ ]”.

Posts “How To Make Gold On Led Strip Lights” posted by on 2021-10-22 18:01:09. Thank you for reading the article at wallx.net