How To Make A Pressure Pot For Casting

As promised, I will continue down the path of stabilizing and casting “worthless” wood by explaining how I build my pressure cooker and accessories. If you missed the previous post where I explained How to Create a Vacuum Chamber, you might want to start there. If you’re confused as to why a pressure cooker is needed, the main idea is that while molding harder materials like turpentine, you can pressurize and contract the air bubbles. The great thing about this process is that after the resin cures, the air bubbles remain so small that they are barely visible. As with most projects, watch the VIDEO! Please SIGN UP if you haven’t already. Before I get started, I’d like to share a few projects I’ve done recently with composite blanks made using this process. If you haven’t seen the Make a Hybrid Marking Knife article/video, it should definitely be on your next list.

Safety

Shopping list

Contents

Read more: fire symbol awakens how to get anna | Top Q&A Depending on the type of setup you decide to build, you’ll need a different type of adapter. I will try to put together a complete list and mark the items as required or optional. One thing to remember when buying adapters is that the thread used is the NTP (National Pipe Thread) standard. I would also like to mention that you don’t need to buy any of these online. Most Harbor Freight stores should have most if not all of the adapters you need and for a pretty good price.

- Harbor Freight Air Pressure Paint Bucket (Required)

- Replacement paint tank (Slightly more money but looks better built.) (Optional)

- NTP cap 1/4

- NTP 1/4 Female / Female Ball Valve (Required)

- NTP 1/4″ Male Quick Coupler (Required but make sure it fits your compressor hose.)

- NTP reducer 3/8 Male to 1/4 Female (Required)

- Elbow 1/4 Female to Male (Optional)

- Teflon Thread Tape (Required)

- HDPE Sheet (Optional)

Meeting

Other resources of pressure cooker

- Handbook for transporting goods at the port

- Zack Higgins – Setting up a cargo pressure vessel at the port

- Dema – Set up a pressure cooker for casting

Set up for the first time

Set up for the first time

Before connecting the compressor for the first time, there are a few things you will want to do. The first thing is to sneak into the house, get some kerosene and apply a patch around the rubber gasket on the cap. This will help get a proper seal so you may want to keep it around and apply it whenever the pressure cooker is in use.

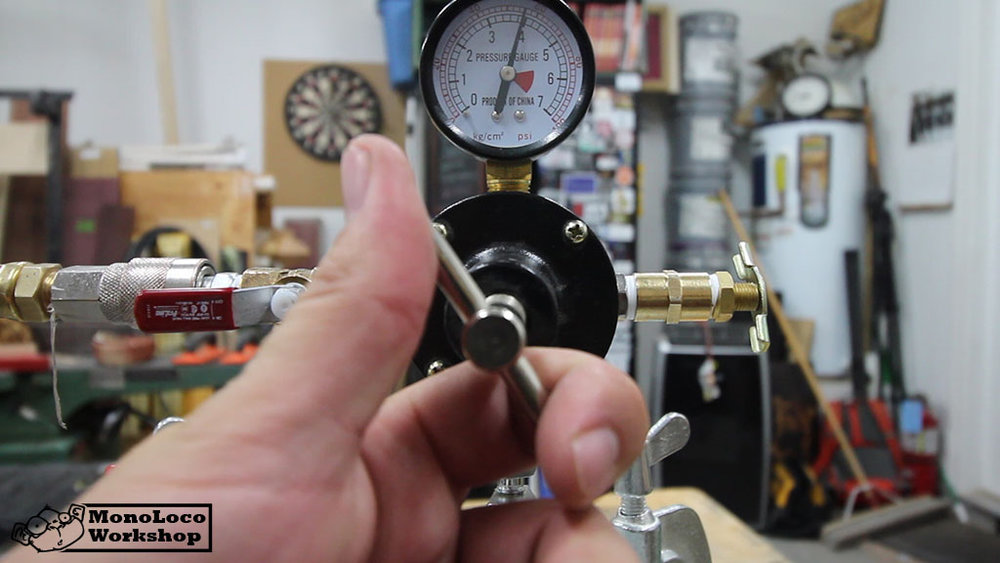

Pressure regulator

Getting regular dial pressure is pretty easy. Turn it to the left and the maximum allowable pressure drops. A little twist to the right and the allowable pressure increases. Before plugging anything in, you can rotate it to the left a few turns and then slowly bring it up until you reach maximum pressure. (I set mine to around 55 PSI.) You also need to remember to reset your compressor regulator at this point to make sure the pressure vessel regulator isn’t set too high.

Safety release valve

To adjust the relief valve safely, there is a small plate that goes around the spring-loaded latch that you can pull out to relieve pressure. In general, you can stick a small flat-head screwdriver or your fingernail down there and rotate the disc left and right. Moving this plate is actually tightening a spring underneath to regulate the pressure the valve will activate. While you’re adjusting the boost pressure up to your optimal operating pressure, chances are the safety relief valve will come into play, which may startle you because it’s huge. If this is the case, turn the disc to the right slightly until the valve closes. If it won’t turn off, that means it’s set to high and you’ll want to set your pressure to the active PSI and reduce the valve’s trigger pressure until it turns off and then back on. just a minute. See also: how to make balloons float from the ceiling To maximize your pressure cooker casting experience, there are a few accessories you’ll want to make. The first is the mold tray to help insert the mold into the pot, and the second is the molds.

Pressure cooker mold holder

Pressure cooker mold holder

There are two good reasons to make a pressure cooker holder. The biggest reason is because the bottom of the pot is concave, so it is difficult to put the mold down and completely flat. The second is to add some flexibility to the molds you are using and gives you the option of casting multiple samples simultaneously. I made mine with an adjustable holder in the form of multiple screw holes in case I wanted to pressurize two castings at once.

Mold

To make any kind of molding, you will need a mold or a template to pour the plastic into. I’ve seen many people use melamine but have heard enough horror stories to keep me away, unless it’s a one-time transaction. I love using HDPE as my mold material, which is why you’ll find it on the shopping list above. Not much stick to it and not very expensive either. I won’t go into the details of mold making because depending on the type of drum you want to cast your mold will be different.

Last, Wallx.net sent you details about the topic “How To Make A Pressure Pot For Casting❤️️”.Hope with useful information that the article “How To Make A Pressure Pot For Casting” It will help readers to be more interested in “How To Make A Pressure Pot For Casting [ ❤️️❤️️ ]”.

Posts “How To Make A Pressure Pot For Casting” posted by on 2021-11-04 18:10:29. Thank you for reading the article at wallx.net

Set up for the first time

Set up for the first time

Pressure cooker mold holder

Pressure cooker mold holder