How To Inlay Metal Into Wood

Video How to Inlay Metal into Wood I’ve always liked the feel of contrasting materials, especially metal and hardwood. Metal is the yin and yang of wood: cold, sharp, and uncompromising, while wood offers smooth, supple, and organic grain. When I really want to make a piece stand out, I put in a little effort into mating non-playable partners for visual appeal and a little bit of “how did they do it?” any?” My youngest aunt turns 5 this month, and I’ve built a keepsake box that I hope she will have for the rest of her life – a heirloom that I want to stand out with. timeless, personal and familiar way. I decided her original metal inlay would be a great way to make it her own. Adding a metal coating to a project is easier than you think, with just a few simple tools I used a rotary tool, a Bernzomatic TS8000 soldering iron and a cast iron ladle. Metal ingots are available online for about $30 each, which is more than enough for some inlay projects.

Direction

Contents

Step 1: Build your project

I’m making an 8″ x 12″ souvenir box with cherry sides and a solid walnut top. The silver metal really stands out on the dark walnut top. I gathered everything together and cut off the top, then sanded it square, flat and smooth to 800 grit. The top of the box will be less noticeable at this point as we’ll be peeling off a layer to make the metal flat. The box is basically finished at this point, except for the top and a good finish. I put everything else but the top aside and got down to the prep work. Read: how to inlay metal into wood

Step 2: Lay out your design

Once the box was built, I measured the size and position of the coating then printed it on paper. With the molten metal inlay, avoid too many details or thin areas where heat can burn. Other than that, simply chic isn’t it? I sprayed some adhesive on the paper and carefully glued it where I wanted it. Once it was firmly attached, I carefully smoothed it with a plastic card to remove any air or wrinkles. At this point, really double check your work. This is a time of no return so a few breaths before you dive in is worth it.

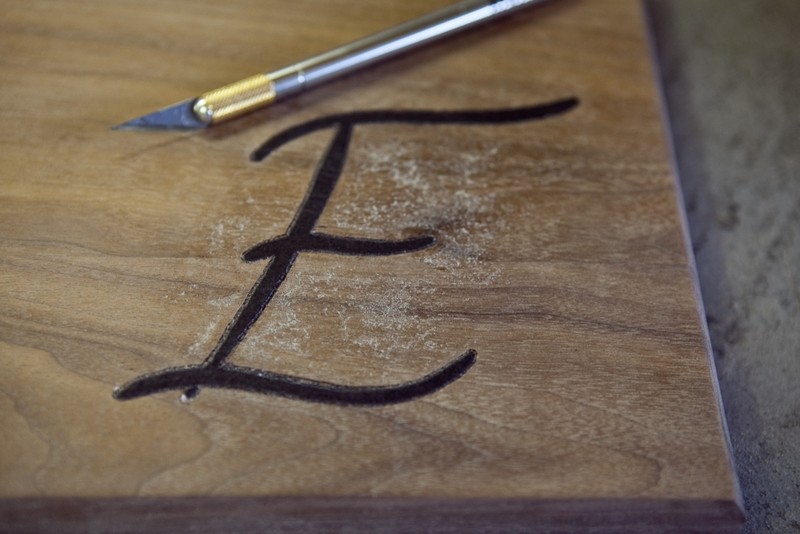

Step 3: Track and score

I used a sharp razor to carefully trace the wood along the contours of the design. Make sure to capture every angle. Once it’s fully inscribed, tear off the design and mark the outline with a permanent marker to get a dark silhouette to work with. Be sure about the lines, because it’s easier to make adjustments now than when you started cutting.

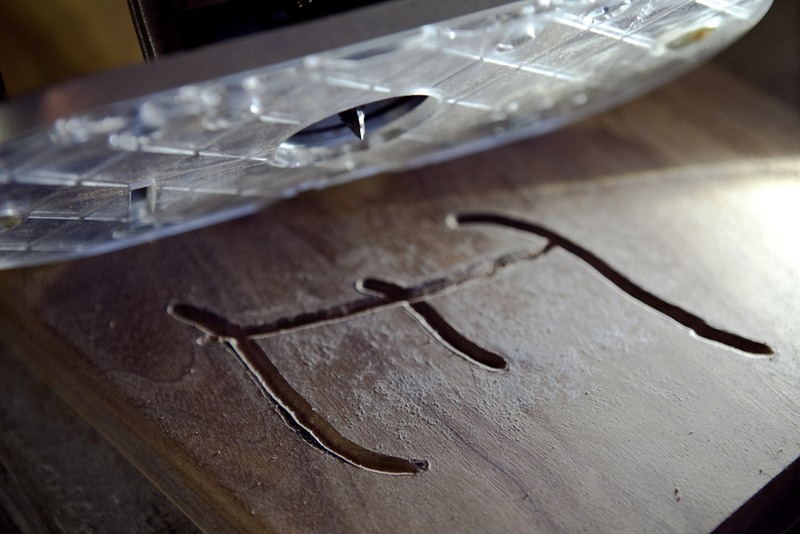

Step 4: Take out the wood

I used a bit of triangle point on my palm router to get most of the wood out of the design. Don’t worry about getting everything, you can clean it up later with a smaller controllable rotator. Watch your depth, aim for you to go only half of the piece of wood, but at least 1/8-“1/4” for good hold. Once the center is out, you should have a nice indentation that you can trim with a small groove on the rotary tool. This is to ensure that the metal holds the wood firmly under the surface and won’t bounce off when the wood is moved or used. I drilled down carefully, then put a small angle into the depression and removed the wood. Take it slow and if it is smoking come back up a bit and let the wood cool a bit.

Step 5: Fine-tune

At this point, look closely at the top edge of the contour and clean up any rough or jagged spots. Look for undercut areas where they are deep and wide enough to provide enough holding force. I also remove the adhesive and any remaining paper from the pattern. Read more: How do you pronounce Moët?

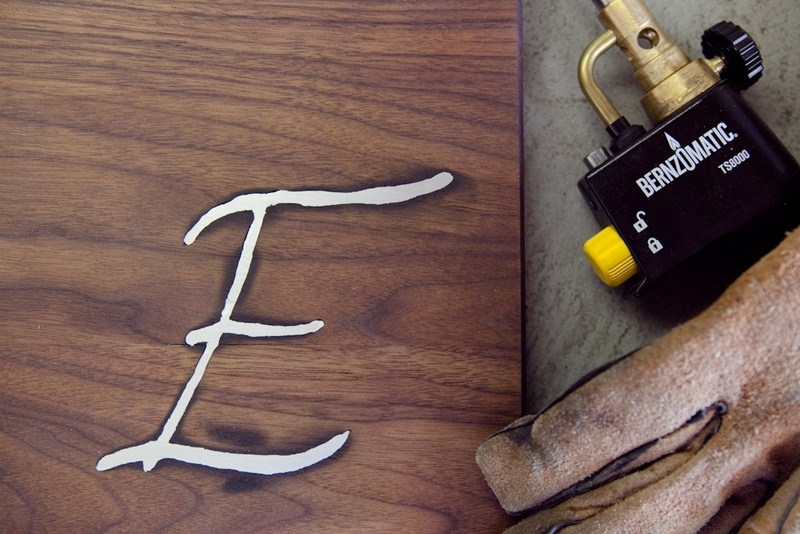

Step 6: Prepare the area

When we are ready to pour, take a minute to prepare the area properly. The molten metal belongs to your workpiece, not to your feet. I cleared all combustible materials and made sure the workpiece was stable on the bench. I opened the door and made sure that the ventilation system would let the air out, but not directly on the workpiece. I also planned on where to place the hot torch and heating ladle when I was done with that. I also planned where to start pouring to expedite the flow of the molten metal. I used a hacksaw, but you can use a hacksaw, or just melt the end into a ladle.

Step 7: Pour metal

I slowly melted the metal by lighting the flame directly into the ingot. The melting point is about 460 degrees Fahrenheit, so it melts in just a few seconds.

Step 8: Finish your metal mosaic project

Metal can be sanded after it is cool enough to touch. I used a belt grinder for most of the material and an orbital grinder up to 800 grit to really polish it. I wipe over a layer of polyurethane to seal and protect it. It is now ready to be passed on to the next generation to hold a collection of special memories as it grows into a treasure of its own.

Advice

Things to keep in mind when working with molten metal and wood– Keep safe. This is molten metal and it will definitely burn anything it touches. Keep hands and other skin covered with flame retardant materials such as leather gloves and aprons. Also, make sure all pieces are stable and don’t tip over when heating or transferring metal.– Be sure to tilt the edges slightly to make sure the metal doesn’t bounce off the wood when movement occurs. – Keep it simple. Intricate designs will be difficult to complete with this type of work, thin wood will burn or peel off when sanded. The face of the box is made from walnut, so it is a hard wood, quite heat resistant. avoid using softwoods as they tend to burn with heated metal.– Use lead-free metal, and work in a well-ventilated area to avoid inhaling fumes from molten metal. I used a mixture of 97% tin, 2.5% Antimony, and 0.5% copper for my ingots in this project. Read more: how to make a larva sword | Top Q&A

Last, Wallx.net sent you details about the topic “How To Inlay Metal Into Wood❤️️”.Hope with useful information that the article “How To Inlay Metal Into Wood” It will help readers to be more interested in “How To Inlay Metal Into Wood [ ❤️️❤️️ ]”.

Posts “How To Inlay Metal Into Wood” posted by on 2021-09-04 02:07:39. Thank you for reading the article at wallx.net