How To Fix A Bike Pedal Crank

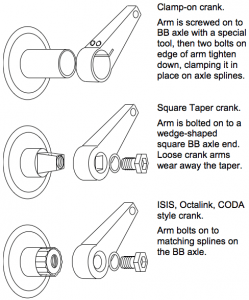

If your crank arms “sag” with each pedal stroke, or if you can swing them from side to side, fix them now before they become irreparable. frame shaft. If this doesn’t work – the crank comes loose after a short time or the latch is missing – there are more drastic measures. The most recent types of bottom racks and cranks are available outer bearing. You can tell if you have this if the sections of the bottom bracket that screw into the frame are fairly wide (1cm or wider). Also, quite often the bottom rack shaft is either completely hollow (you can see the whole way through it) and one of the cranks clamps onto this shaft, or the shaft is hollow but has only one pin on one side. . clamp on handwheel with a hollow-bottom rack shaft with a through shaft attached to the driven side crank, and the non-drive side crank with two bolts through it to clamp to the other end of this shaft. You must loosen these clamp bolts before you can tighten the crank back to the shaft using a tension bolt – usually this tension bolt is tightened with a special tool that is not fixed to the bike . If you don’t have it with you, improvise by tapping the bolts around with a screwdriver. Do not over-tighten the tension bolt. This exists purely to bring the crank arm close to the bottom bracket. Once the tension bolt has been tightened, the clamp bolt must be tightened again to hold the crank in place. If necessary, an additional washer can be fabricated. If one of the clamp bolts is missing, find a replacement – water bottle cage bolts, lever clamp bolts, shoe clip bolts, all of which may fit. Read more: The Complete Guide to Finding and Selling Ecommerce CustomersOther hollow bottom frame shaft type has latch on one side – usually the drive side. The latch can be hidden behind the dust cover. The shaft is permanently attached to the other crank. Fixing these crank sets is very similar to fixing the other bolts described below. bolts on both sides looks like it will thread into the bottom bracket shaft, you have a Square taper, ISIS, CODA, Octalink or similar repair method. Again, there may also be a plastic or metal dust cover on the crank where the bottom rack shaft will poke through, or even another piece of metal that allows you to see the bolt but can’t completely remove it. whole. You can put quite a bit of force on the tool you’re using, perhaps by using the help bar. If the tightening doesn’t work (or works, but the bolt soon loosens), read on…Square cone bottom bracket that’s all – a square, pointed end to the bottom rack shaft. Sometimes they wear out too small, so try to cover the rack interface from top to bottom with aluminum strips maybe or similar. ISIS and other designs where the drive-side crank slides into a curved (wavy) piece of pipe, try some sort of threadlock solution between the bottom bracket and the crank. Read more: how to connect poly hose to pvc If the handwheel falls off and you lose a bolt, at least make sure you have the crank on the drive side. To remove the bolt from the non-drive side, you may need a helper bar for extra leverage. Take the bolts (and washers behind it) from the non-drive side and use them to reattach the crank on the drive-arm side. The non-drive side crank can be temporarily placed at least without a pin through it, but don’t put pressure on it as you drive, as this will loosen it quickly.

- If you find a piece of metal on the crank arm bolt that allows you to see the bolt but cannot remove it, this is a self-expanding bolt assembly. The bolt pushes into the metal as it untwists, forcing the crank to simultaneously bounce off the bottom rack shaft. In this situation, you don’t want this to happen, so remove the metal piece first. The metal piece will likely untwist clockwise (reverse thread), and will require a 10mm Allen wrench or judicious use of a screwdriver or other sharp object in the keyholes of the locking ring on the face of the device. it.

Remove handwheel

During the repair of bicycle parts, you may encounter the opposite problem – removing the crank. Usually this requires a special tool (or self-retracting bolt), but if you unbolt and cycle (gently) a bit, the crank will be loose enough to be removed by hand. Only do this as a last resort, as it may damage the crank and BB.

An explosion from the past

There is another type of crank accessory that we have not covered so far. If the crank has a nearly circular piece of metal that slides through it, perpendicular to the bottom rack axis, with a pin on the other side, you have a Cotter Battery winch.

Last, Wallx.net sent you details about the topic “How To Fix A Bike Pedal Crank❤️️”.Hope with useful information that the article “How To Fix A Bike Pedal Crank” It will help readers to be more interested in “How To Fix A Bike Pedal Crank [ ❤️️❤️️ ]”.

Posts “How To Fix A Bike Pedal Crank” posted by on 2021-10-29 21:46:06. Thank you for reading the article at wallx.net