How To Do File Work On A Knife

Step by step instructions in the photo

Contents

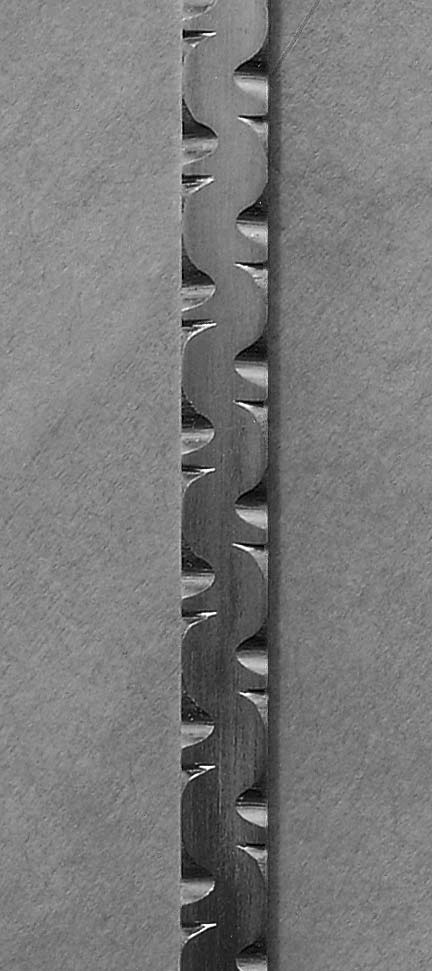

Vine filework is my favorite profile style. If you break it down into small steps, it’s very easy to do. The materials you will need are a Sharpie® marker, vise, and a 5/32 inch round file and a small triangle file. You can use a larger round file on thick-edged materials, or a smaller round file when engraving thin backing or blades. sharper than the other two corners. This provides a safe left and right side to open your grape file cuts, as well as give them sharp points.

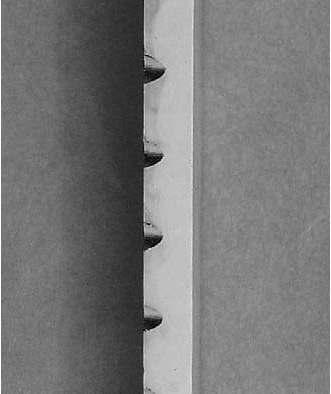

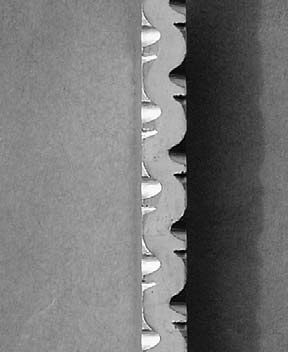

STEP 1

Using your Sharpie® marker, make semicircular marks approximately 5/16 inch apart down one side of the blade spike. (Though not shown here, make sure to keep the blade firmly in a visor.) (Hayes photo)

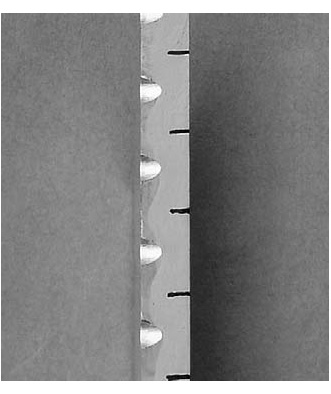

Step 2

Step 3

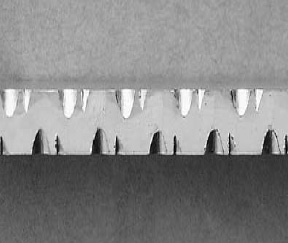

Step 4

Read more: How to make a man cry in the bedroom

Step 5

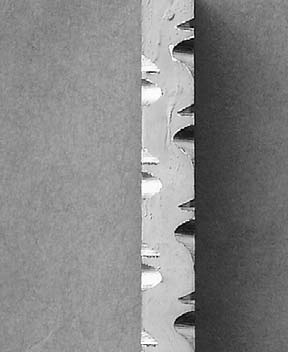

Step 6

Step 7

Step 8

Read more: how to turn off auto android

Step 9

Step 10

Step 11

Step 12 (Finally)

For the 12th and final step, re-scan the entire profiled area with fine sandpaper. Increase the strip of 320 grit sandpaper to 3 inches and place the paper over the circular and triangular file to back the paper. Do not push too hard and tilt the wrap away from the safety edges so that you do not round (square) the safety corners of the profile. Have fun and stay safe. Read more: How to cope

Read on:

- Fit and Finish 101: How to Tell When You See It on a Knife

- Knifemaking: Building a Processing Framework

- Craft a knife by smelting an Iron Bog

- Best knife-to-blade handling ratio

- Meet living legends who make knives

Last, Wallx.net sent you details about the topic “How To Do File Work On A Knife❤️️”.Hope with useful information that the article “How To Do File Work On A Knife” It will help readers to be more interested in “How To Do File Work On A Knife [ ❤️️❤️️ ]”.

Posts “How To Do File Work On A Knife” posted by on 2021-11-05 06:55:13. Thank you for reading the article at wallx.net