how to connect 2 4×4 posts together

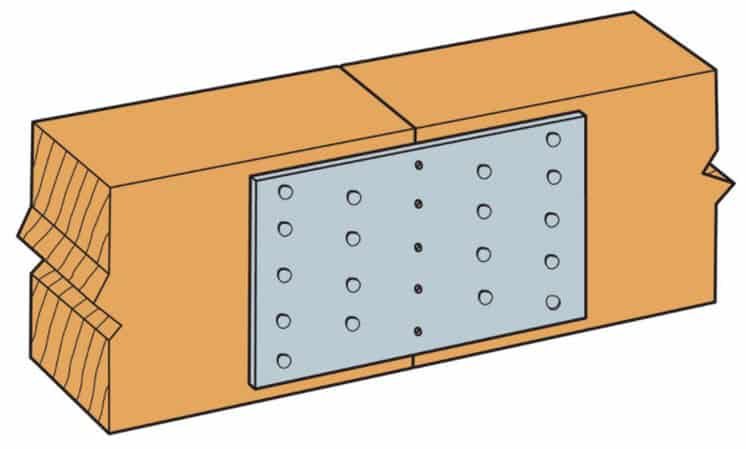

Most DIYers and carpenters have some ideas of how to connect wood together with glue, nails, screws, and bolts. However, when it comes to splicing pieces together for structural purposes, we may admit to needing help. How to connect 2 4×4 posts together is a common question on many sites, so we decided to put together a helpful guide.To connect 2 4x4s use a half-lap joint secured with construction adhesive, two steel plates, and four to six 1/2″ or 5/8” through bolts. Posts that support roofs or platforms should lap between 20” and 24”, other structures should connect for 6” to 10” along the centerline.Reading: how to connect 2 4×4 posts togetherIn this guide, we’ll identify when to splice 4x4s and explain several current methods that are Code compliant. We’ll also identify and explain the strongest way to join 4x4s. By the end of your read, you should understand how to join 4x4s end to end, and when it is acceptable to do so.

When to Connect Two 4X4 Posts Together?

Contents

There are many reasons to join 2 4x4s together. Making a post longer, cut too short, repairing a post, building a longer piece for a skid, and post-to-beam connections are the most common reasons.

Extend Posts

Adding a privacy barrier or roof shelter to a deck is a frequent reason to make existing railing or deck posts taller. Extending fence posts to raise the height of the barrier is another reason to lengthen 4×4 posts.Two other reasons rest on transportation and availability issues. Carrying and connecting two 8-foot lengths is easier than transporting a 16-foot length, especially if traversing woodland trails. The availability of long 4x4s at many small suppliers is often limited due to low demand, making splicing a necessity.

Repair

Wood is susceptible to rot or damage. Repairing a 4×4 is usually easier than dismantling and rebuilding a fence, deck, or other structure. Especially if the post is set in concrete or supporting other pieces. Figuring out how to hold everything up while repairing the 4×4 may be more difficult than the repair itself.

Build Long Skids

Joining 4x4s for horizontal use instead of vertical use is done in a similar way. The orientation of the cuts should maximize lateral strength while preventing the retention of penetrating moisture. The stresses applied to the skid will also affect the type and orientation of the connection. A pull force versus a downward force affects the joint differently.

Post to Beam Connection

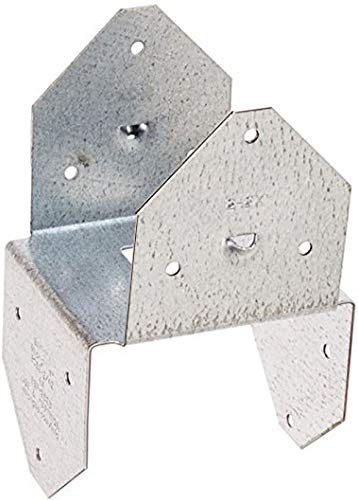

Fastening a 4×4 post to a beam or beam to a post can be done in a variety of ways depending upon the purpose and where the connection occurs. Using specialized brackets is a common way to secure pieces together and support a butt joint. A Mortise and Tenon connection will look better but may not provide the necessary support strength due to the dimensions of the wood.

How To Connect 2 4X4 Posts Together: Most Popular Ways

Carpentry and joinery are ancient trades packed with specialized terminology and tools. A scarf joint is any connection where two pieces of wood overlap or lap flush in the same grain direction. Connections must withstand vertical and horizontal forces or stresses, so it is important to consider those when choosing a joint. Strength and resistance to compression or tension can be improved with glue, straps or plates, and bolts.There are a number of popular ways to connect two 4x4s together to extend their length, some are easier than others. It is advisable to check local Codes for any requirements and have a Structural Engineer check it, especially if it will support or cover people. Additionally, any cuts or holes into treated wood should be painted with an end-cut solution containing Copper Naphthenate or Sulfate.Pro Note: When using untreated or galvanized metal on pressure-treated wood it is recommended the contact surfaces be protected with bitumen tape. The tape helps prevent corrosion, and seals against moisture. Always use stainless steel or coated fasteners with pressure-treated wood. Hot-dipped galvanized will last longer than untreated steel fasteners, but stainless will outlast them all. If near saltwater, stainless steel bolts and plates are better than hot-dipped galvanized ones.

Butt Joint With Steel Plates

- Quick, simple, and easy to install

- Good vertical strength

- Staggered fasteners prevent splitting

Read more: How to change entity crammingCons

- Poor lateral strength

- Difficult to align

- Not aesthetically pleasing

Half Lap Joint

- Easy to make

- Very strong vertical and lateral joint

- Excellent long grain to long grain connection

- Resists twisting

Read more: How to change entity crammingCons

- Saw skill

- Accuracy

- Time-consuming

Dowel Joint

Lengths of 3/8” to 1-1/4” dowels can be used to add lateral strength to butt joints. Carefully measure to bore and align 1 to 4 holes in the ends of each 4×4 and drill the holes between 1” and 3” deep. Cut the dowels to lengths of 2” to 6”, sand the cuts, glue, and tap into place.Coat the protruding piece of dowel with glue, or pour some glue in the holes of the upper pieces, and push it onto the dowels. Tap into place with a hammer if necessary.Similar butt joint reinforcement connections may be made using two to four biscuits inset into matching grooves cut into the ends of the 4x4s. Alternatively, cut a matching groove in the butt ends and glue in a wooden spline. Dowels, biscuits, and splines all reinforce the alignment and provide some lateral reinforcement.The use of dowels for butt joints connecting light-use posts is often helpful. However, for structural purposes, attach two steel plates with structural connector screws or 1/2” through bolts to opposite sides of the joint is commonly required to add more strength too.Read more: how to clean rainbow flip flops leatherPros

- Improve lateral connection

- Inexpensive joint

Read more: How to change entity crammingCons

- Difficult to vertically align accurately

- May produce a shear fault

Butt Joint With Hollow Pipe Insert

A hollow 10” to 24” metal pipe, 1” to 1-1/2” in diameter, inserted into a hole drilled vertically into the center of the ends of the two 4×4 to be butt joined, provides additional lateral reinforcement. The pipe is secured into the vertical holes with construction adhesive. Two 1/2″ through bolts are inserted into the top and bottom post pieces in holes bored through the wood and pipe.Read more: how to clean rainbow flip flops leatherPros

- Improved lateral resistance

- Less visible connection

- Strong vertical joint

Read more: How to change entity crammingCons

- Special tools required

- Post may twist out of alignment

- The pipe weakens the lateral strength of wood

Modified Half Lap Joints

- Strong lateral and vertical seam

- Highly aesthetic joint

Read more: How to change entity crammingCons

- High level of skill

- Require more time

Interlocking Tapered Scarf Joint

- Stronger than half-lap or butt joints

- Withstands twists and bends

- Strong vertical and lateral connection

- Ideal for skid or post extensions

Read more: How to change entity crammingCons

- Measurements accuracy

- Cutting skill

- More difficult than the half lap

Post Cap/Base Brackets

- A quick and simple connection

- Some vertical strength

- Easy to install

Read more: How to change entity crammingCons

- Weak lateral resistance

- Not aesthetically appealing

What Is the Strongest Way to Join 2 4X4 Wood Posts?

Joining 4x4s together to extend their length can be as easy as a butt joint or as complex and elaborate as a keyed, double tenoned scarf joint. However, some cuts are better done where the timbers can be rolled easily and joints tested for alignment and fit. When working on posts under load or limited space, simpler connections are better.Our choice for the strongest and easiest way to join two 4×4 posts is a half-lap joint that is glued, plated, and bolted. Cutting a half lap into an existing fixed post is easier than all other cuts, except the butt joint. The two required cuts per post are simple and doable even with limited space.A glued, plated and bolted nibbed tapered scarf joint is stronger than a half lap but not as easy to cut in limited space. Although it too has two cuts per 4×4, accurate sawing is more difficult. The skill level and aesthetics of the finished joint influence the choice of connection. A poorly sawn joint won’t make for a strong connection.

Conclusion

The best way to join two 4x4s to extend a post is with a half-lap. The simple cuts make it ideal for a beginner or pro to make, and it’s easier to do in limited space. Adding glue, plates, and bolts increases the lateral and twist resistance to form a very strong connection.Hopefully, you have a better understanding of how to connect two 4x4s, and which joint will provide the strongest connection. If you found the guide helpful, please share it with others. As always, your comments and suggestions are appreciated.Read more: How To Wear Leg Warmers: Top 13 Style Checks

Last, Wallx.net sent you details about the topic “how to connect 2 4×4 posts together❤️️”.Hope with useful information that the article “how to connect 2 4×4 posts together” It will help readers to be more interested in “how to connect 2 4×4 posts together [ ❤️️❤️️ ]”.

Posts “how to connect 2 4×4 posts together” posted by on 2021-08-27 02:23:29. Thank you for reading the article at wallx.net