How To Clean A Holley Carburetor

Carburetor cleanliness is absolutely critical. Any small particles such as dirt, sand, etc. can easily clog small ports and passages. Buildup of carbon, old grease, and so on can hinder movement of shafts and other moving parts. During any service or rebuild, take the time to ensure that every single component is absolutely clean and free of contaminants. Although a parts cleaner certainly comes in handy, it’s highly recommended to use a dedicated solvent that is specifically designed for carburetor cleaning. You also need a few cleaning brushes of various sizes that should be dedicated to carb cleaning only to eliminate cross-contamination. Old general-use brushes may contain grit and other deposits because they may have been used to clean various engine, brake, suspension, or other parts.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorThis Tech Tip is From the Full Book, HOLLEY CARBURETORS: HOW TO REBUILD. For a comprehensive guide on this entire subject you can visit this link:LEARN MORE ABOUT THIS BOOK HERERead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorSHARE THIS ARTICLE: Please feel free to share this article on Facebook, in Forums, or with any Clubs you participate in. You can copy and paste this link to share: topqa.info/tech-tips/how-to-inspect-clean-a-holley-carburetor-step-by-step-guide/Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorYou also need a source of compressed air to blow small passages clean. This can be accomplished with a shop air compressor or hand-held bottles of compressed air that are available at office supply stores (the same type used for cleaning computers).Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Solvents

Contents

Although a spray-can of a brake-cleaning solvent may provide a reasonable cleaning choice, a specific carburetor cleaning solvent is a better choice because of its formulation. This cleaner, along with a small soft-bristle brush, can accomplish your goal. However, to remove even the most stubborn varnish or carbon buildups, a specially formulated carburetor cleaner, such as CRC Industries’ TYME-1 provides superior cleaning performance. This solvent is available in both 1- and 5-gallon buckets.TYME-1 is rather aggressive and is intended for metal parts only. Any soft parts, such as O-rings, gaskets, and diaphragms should be replaced. Even though some O-rings and diaphragms may appear reusable, if you’ve completely disassembled the carburetor, it just makes sense to do it properly and start off with fresh seals, diaphragms, and gaskets.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorDedicated carb solvents, such as TYME-1, are very potent. You must wear protective gloves and safety glasses when dealing with this chemical. Just immersing the parts in a bucket of this solvent removes contaminants. Depending on the severity of the buildup, a soak time of 15 minutes to an hour usually does the trick. To avoid losing small parts in the bucket, and to prevent having to dip your hand into the solvent to retrieve parts, place all parts in a parts-washer cleaning basket. The basket is made of perforated steel that allows the solvent to drain when it’s removed from the bucket; it also has a tall handle for ease of dunking and removal.After soaking the parts in solvent, rinse them in hot water to remove chemical residue. Blow dry with compressed air, paying particular attention to blowing out all passages and orifices.Don’t get carried away with air pressure. Adjust the regulator on your compressor to about 25 to 30 psi. Excessive air pressure can potentially dislodge any internal pressed-in plugs, which can ruin your main body and turn it into an expensive paperweight.

Cracks and Pinholes

If you don’t have access to expensive flaw-detection equipment, an easy way to check for cracks is with a dye-penetrant kit and an ultraviolet (UV or “black light”). These kits include three hand-held aerosol spray cans: One cleans and prepares the surface, one is a dye-penetrant spray, and one is a developer spray. You can use the following three steps with most kits.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

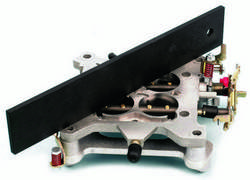

Main Body

Check the metering block mating surfaces of the main body for flatness with a precision straightedge and feeler gauge. If warpage is found to be more than .007 inch, you can try to resurface the area by carefully using a clean and sharp, broad flat file. First, make sure that the surface is clean and dry. Then, wipe machinist’s dye across the surface and allow it to dry. Using a clean flat file, carefully and lightly file across the surface. The dye is quickly removed on high areas and remains on low areas. Although an ideal surface is perfectly flat (with all dye removed), this really isn’t necessary.As you proceed, check your filing with a straightedge and feeler gauge. A maximum of approximately .006-inch deviation is acceptable because the new gasket should be able to seal with that minimal amount of unevenness. File very carefully to avoid creating an uneven surface. Don’t dwell on one particular area, and make absolutely sure that the file is always held parallel to the surface. Move the file across the entire surface with light strokes.Also check for flatness at the main body’s accelerator pump mounting flange. It’s rare for this surface to be warped, but as long as you’re checking, it’s worthwhile. Again, if using a flat file, the main body must be secured. If the body moves during filing, you may file unevenly and create more problems and the gaskets will not seal properly.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Power Valve

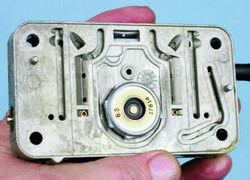

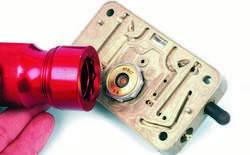

Holley carburetors are equipped with a vacuum-operated powerenrichment system that incorporates a power valve. The power valve threads into the primary-side metering block. A power valve in the secondary metering block may also be located on double-pumper carbs with mechanical secondaries. This prevents a lean condition during WOT operating conditions. Placing a power valve at the secondary metering block is of particular benefit if the engine has forced induction, such as a supercharger, where the power valve is able to supply additional fuel to the main system during heavy loads or WOT.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorIdentification NumberA Holley power valve is always labeled with an identification number, such as 3.5, 35, 4.5, 45, 6.5, 65, which translates into the power valve’s vacuum rating. Even-numbered power valves are not available. Some numbers include a decimal point and others don’t; the decimal point is irrelevant.For example, both 65 and 6.5 indicate a vacuum rating of 6.5 inches of vacuum. This is the point at which the valve opens and the engine vacuum drops to that point or below it. Manifold VacuumHolley power valves have a cast metal housing, a rubber diaphragm, and a spring. When engine vacuum drops to and below the valve’s rating, the valve opens and allows extra fuel to flow through a calibrated port in the metering block, which is called the power-valve channel restrictor. A blown power valve (from a failed diaphragm) results in an over-rich condition, allowing full-time fuel enrichment. The same problem occurs if the incorrect power valve is installed for the application. This obviously results in lousy fuel economy, spark plug fouling, poor idle quality, and black smoke from the tailpipe.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorAn unmodified stock engine probably has an engine vacuum at idle in the 18- to 20-inch range. A high-performance or competition engine that’s equipped with a long-duration high-overlap camshaft produces a lower engine idle manifold vacuum.When inspecting for manifold vacuum, be sure to allow the engine to warm up to full operating temperature before taking a vacuum reading. A simple vacuum gauge connected to a full manifold vacuum port may be used when checking engine vacuum. Before taking a vacuum reading, bear in mind that if the vehicle is equipped with an automatic transmission, the transmission should be placed in gear, with the brake on, and with the engine at idle. If the vehicle has a manual transmission, place the transmission in neutral and check manifold vacuum at engine idle.Size SelectionHow do you determine what size power valve to use? The power-valve rating should be half of engine manifold vacuum. For example, if manifold vacuum is 13 inches, the correct power valve is a number 65 (rated at 6.5 inches of vacuum). If, when manifold vacuum is divided in half, the resulting number is an even number, always select a power valve with the next-lower reading. For example, if manifold vacuum is 8 inches, select a power valve rated at 3.5 inches. If you’re tuning for performance, a higher-numbered power valve allows an increase in fuel enrichment (a 65 valve allows more enrichment than a 45, for example). For optimum track performance, expect to perform a few trial-and-error experiments with higher-numbered power valves.Power Valve TestingTo inspect for a suspected blown power valve, have the engine at operating temperature and idling, then turn the idle-mixture screws (on each side of the metering block) all the way in. If the engine begins to stumble and dies, it is an indication that the power-valve diaphragm is not blown. If the engine does not stumble and die, the power valve is likely faulty.Power valves are screwed into the metering block, which has a thread size of 1/2-27. The head of the power valve has four flats for wrench engagement and may be removed using a 1-inch wrench. However, the flats are relatively shallow with a height of about .120 inch. Take care to avoid burring the flats or damaging the metering block surface.An aluminum power-valve wrench is available from select sources; it is designed specifically to securely and safely engage the power-valve flats. If you plan to service Holley street or competition carburetors on a regular basis, I recommend purchasing one of these tools from a source such as Willy’s Carburetors.Another specialty tool is available to vacuum test a power valve with the power valve removed from the carb. These testers are readily available from sources such as Moroso and Willy’s Carburetors.This specialty tool allows you to bench test a power valve with a common handheld vacuum pump. Simply unscrew the head of the power-valve tester tool and then screw the power valve into the tool’s main body port. A rubber O-ring seals the tool to the power valve. Reinstall the tool’s head, which seals to the tool main body with another O-ring. Connect a hand-held vacuum tester’s hose to the 1/8-inch fitting on the tool’s head, and operate the vacuum pump.The pump’s gauge allows you to monitor the opening point of the valve. A handy window is built into the aluminum tester tool that allows you to visually check if and at what point the valve opens. You can then determine if you have a faulty power-valve diaphragm and easily verify the level of vacuum when opening occurs. In addition, you can verify the rating of the power valve by observing the vacuum pump’s gauge reading as the valve opens. Using this type of testing tool eliminates guesswork and allows you to verify power-valve condition and operation.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorPower Valve TestingStep 1:Separate Fuel Bowl from Metering Plate

Throttle Plates

Inspect the throttle plates for damage. If the carb was laid on a workbench while someone held the throttle open, for example, the plates may be bent. If the plates are bent, you must replace the choke plates. The staked screws that secure the plates to the shaft or the entire throttle body also need to be replaced. With the throttles closed, there should be a small gap between the primary throttle plates and their throttle bores, as set by the factory. The plates should not be seated fully. They are supposed to be open slightly for idle quality. This is likely in the range of .010 to .012 inch, depending on the model.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Choke Fast-Idle Cam

Inspect the plastic fast idle cam (behind the choke housing) for wear, breaks, cracks, etc. If any of the steps in the cam appear worn or damaged, replace the cam.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Throttle Shaft and Shaft Bearings

Keep in mind that in addition to vacuum leaks, a distorted or warped baseplate throttle body can also result in throttle shaft binding. If the throttle shaft is bent or untrue, it can be especially noticeable in vacuum-operated secondary models because the vacuum diaphragm may not be able to open the secondary throttle plates. If a throttle shaft is bent, replace the shaft or replace both the throttle body and the shaft.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorInspect the throttle shaft (with the carb disconnected from the vehicle’s throttle linkage) by wiggling the shaft up and down. Any detectable vertical movement indicates that the throttle shaft bearings are worn. This requires that the throttle body be replaced. A competent carburetor rebuilder may be able to re-bush the throttle shaft bore.Overtightening the carb to the intake manifold, especially when using a very thick and soft gasket, can also contribute to shaft binding.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Idle and Main Well Passages and Emulsion Tubes

Under typical circumstances, preparing to clean a metering block should involve simply removing the idle-mixture screws. When fuel flow through the main system begins, fuel is metered through the main jets and into the main well in the metering block. As fuel travels upward through the main well, air is added from high-speed bleed orifices in the passage to emulsify (pre-atomize) the fuel charge, and then it travels through the discharge nozzles. This air-charged fuel delivery is lighter in weight and is able to respond faster to changes in the venturi vacuum signal.The tiny air orifices can be clogged if the carburetor was previously subjected to severe contamination. Unfortunately there’s no way to verify this without removing the press-fit plugs from the metering block. The top of the metering block has cap plugs that seal the main and idle well passages. Depending on the carb model, removing the press-in cap plugs may reveal the main and idle wells, but some plugs may include an emulsion tube attached to the plug.To remove the cap plugs and/or plugs with emulsion tubes, carefully drill a 1/8-inch hole in the center of each cap plug. Next, thread in a No. 8 sheet-metal screw into the plug, leaving the head of the screw well exposed above the plug. This gives you something firm to pry against; then, pull the plug out using a pair of small crow’s-foot pry bars. Be aware that drilling too deep can easily damage any integral passages that may be present under the plugs and you can easily ruin the metering block. Don’t drill more than 1/8-inch deep.The cap plugs, depending on carb model, may be flat or recessed. If the cap plugs are recessed, carefully measure the installed depth before attempting to remove them because they need to be reinstalled at the same depth. Cupped-type plugs are readily available from Holley (PN 1007-107), but flat plugs are not available. Plugs can be reused if the drilled hole is soldered shut or sealed with an epoxy such as J-B Weld. Care must be taken to avoid excess solder or epoxy from running past the hole and causing an obstruction.If the carburetor, upon disassembly and inspection, shows signs of heavy contamination, your best recourse may be to simply replace the metering blocks, if you don’t feel like taking the time and effort involved in the tedious process of plug removal. If the operation isn’t carried out correctly, you can create more problems.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorBefore installing new or the original plugs, lightly coat the cup outer surface with an epoxy and gently drive the plug into place. Again, if you have cupped plugs, they must be reinstalled at the original depth.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorMetering Block Disassembly and InspectionStep 1: Remove Idle-Mixture Screw from Metering Block

Accelerator Pump Diaphragm

With the accelerator pump cover removed, take out the accelerator pump diaphragm and closely inspect the rubber along the entire perimeter. If any obvious damage such as pinholes, cracks, or tears, is evident, the diaphragm must be replaced. Also check for rubber compliance. If the rubber seems brittle or age-hardened, replace the diaphragm.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Needle and Seat Assembly

Verify that the needle moves freely inside the housing and closely inspect the needle for signs of wear or burrs. Even if you determine that the assembly is okay, always replace the sealing O-ring.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorRead more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Main Jets

As with all other components, the jets must be perfectly clean. Closely inspect the jet orifice to make sure that no debris or varnish buildup is present. The orifice may be cleaned out using a hand drill; never use a power-drill driver. Don’t try to enlarge the jet size. If you need larger jets, just install the appropriate size. For cleaning purposes, refer to the list in “Drill Bit Sizes” in Chapter 7 to determine the correct bit size for the corresponding jet. Only use a drill bit for cleaning purposes.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Discharge Nozzles

The nozzle orifices are tiny and must be inspected for cleanliness. If you have a wire of the appropriate size, run it through the nozzles, clean them with solvent, and then blow them out with air. Under no circumstances should you try to drill the nozzles out. Just make sure that they are clean and free of debris.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetor

Carburetor Renewal Kits

Holley offers an extensive range of renewal kits, available for every model of carb that they make. The kits have everything needed, including the correct small clips, unlike some aftermarket kits that may not be as complete and may not include the correct parts for a specific carburetor. The parts in the Holley renew kits are the same type and quality that was original on the carb from the factory.Read more: how to replace sill plate in basementRead more: how to change blog layout in wordpressReading: how to clean a holley carburetorWritten by Mike Mavrigian and Posted with Permission of CarTechBooks

GET A DEAL ON THIS BOOK!

GET A DEAL ON THIS BOOK!

If you liked this article you will LOVE the full book. Click the button below and we will send you an exclusive deal on this book.

Last, Wallx.net sent you details about the topic “How To Clean A Holley Carburetor❤️️”.Hope with useful information that the article “How To Clean A Holley Carburetor” It will help readers to be more interested in “How To Clean A Holley Carburetor [ ❤️️❤️️ ]”.

Posts “How To Clean A Holley Carburetor” posted by on 2021-11-02 15:43:20. Thank you for reading the article at wallx.net

GET A DEAL ON THIS BOOK!

GET A DEAL ON THIS BOOK!