How To Calculate The Angle Of Stool Leg

Video How to calculate the angle of the chair legsOnce you understand the ‘result’ angles, sawing the table (and chair) is easy. The truth is, it can be quite complicated if you try to calculate everything using trigonometry. But if you take some lessons from other hosts (like I did over 10 years ago), there are easy ways to design and build chairs without the math. scrap metal, 12-gauge steel wire from home center and stapler. We will design and build a simple saw table with five pieces of wood and corners.

What is Rake, Splay & ‘Resultant Angle?’

Contents

When the chairperson talks about the angles of the chair parts, they use the terms “scratch” and “spin” to describe them. Rake is the angle of the leg when you look at the chair from the side. The front legs scratch forward; hind legs scratched back. Splay is the angle of the leg when you look at the chair from the front. Legs spread out, I don’t describe or measure scratch and hit much, except to explain to other builders. Instead, I use what’s called a “result angle” – an angle that describes both rake and oblique. You can calculate this angle using trigonometry, but there’s a simpler way to think of the compound angle for those who consider math a ruthless master. Instead of looking at the chair from the front or the side, you look at the chair from a position in space where the legs don’t appear to be angled. in front of you. Rotate the chair until the leg closest to you looks perfectly 90°. Imagine that one of your eyes has a laser and can shoot a straight line through your legs and onto a chair. That laser line is what the chairpersons call a “line of sight”—an imaginary line through the legs and onto the chair. Place a single bevel on that imaginary line and you can position a foot in space with a single setting on the bevel placed on your line of sight. your bevel gauge. But what if you want to design your own chair? Or do you want to build a table, desk or footstool using the same wood?

Build a model

When I design a chair, I make a simple half-scale model using scrap wood and bendable wire. This method helps me visualize how the parts will look as I walk around the chair. This model also gives me all my resulting angles and lines of sight without a single mathematical equation. I first learned this technique from the book “The Chairmaker’s Workshop” by Drew Langsner, a wonderful book. I then adapted his method to remove all the math. Use it to design a saw table. Take a 3⁄4” piece of pine and cut it to half the size of the finished saw table. The finished top will measure 2″ x 71⁄4″ x 17″, so make your model 3⁄4″ x 35⁄8″ x 81⁄2″. Next, decide where you want the legs and position them on the model. Each leg is located 21⁄2” from the bottom of the pattern and 13⁄4” from the edge. A lot of this is “by eye”, so don’t worry about it too much. Now cut four pieces of 12-gauge wire up to 10″ long. (Note: You can also use coat hanger wire.) This wire will represent the legs of the saw table. Drill a hole through 5⁄. 32” for each “leg” on your model and epoxy paint the wire in the hole. Set your bevel gauge to 7° using a plastic protractor. Look at the model directly from the bottom of the board. Let’s call this. the front of the saw table. Use needle-nose pliers to bend the wire pins so that they are all 7° outward from the top. Try not to scratch. When they all match the protractor. your bevel, change the setting of the bevel ruler to 14°. This will be the rake. Look directly at the saw table from its side and use pliers to bend your pins down 14°. You can have to tweak things a bit so that all pins look the same Read more: how to connect lights in series Rotate the model on its pins and see the result You will be amazed how easy it is to play incorrect viewing angles are displayed wire until they all look the same and the saw table looks stable.

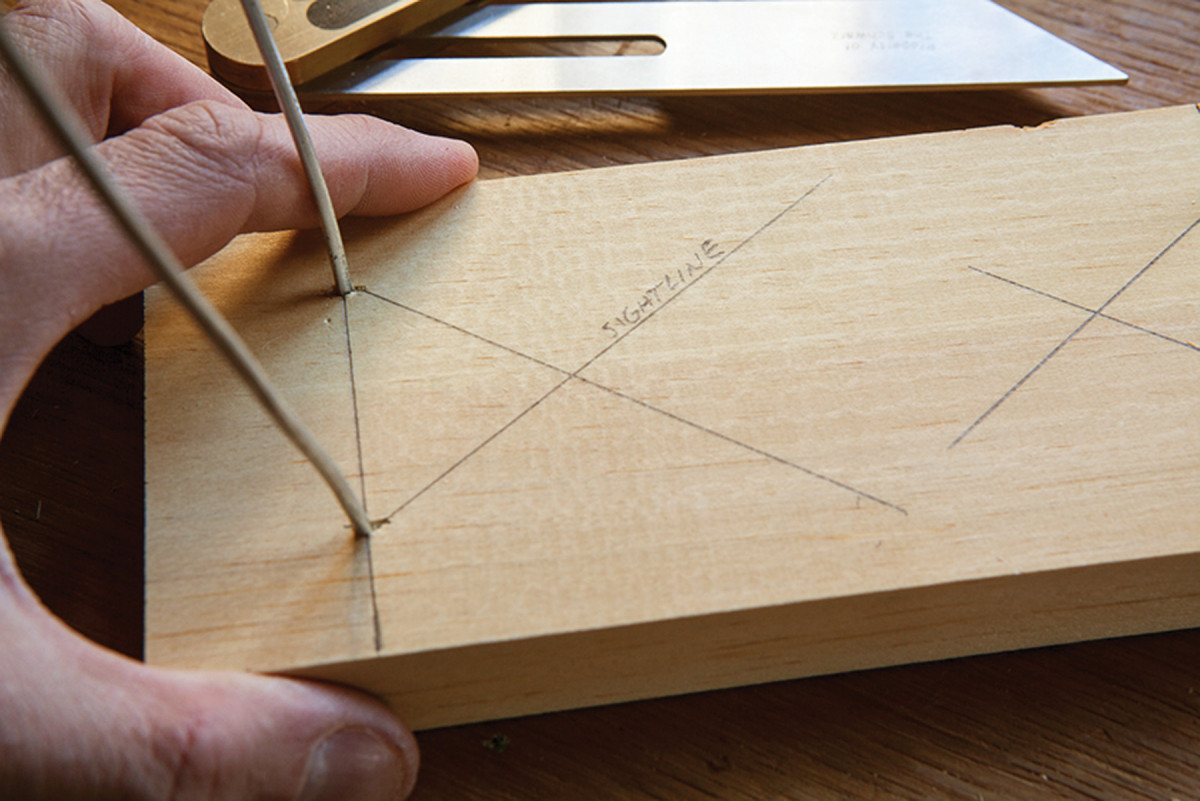

Find Sightline & Resultant Angle

Flip the model over. Place a test square on the bench with the blade facing the ceiling. Rotate the model until one of the pins appears to be 90° from the square. Place the neck of your bevel protractor against the long side of the model and push the blade of the bevel until it appears to align with both the base and blade of your test square. (Hold your head still.)

Construction of Sawbench

Building this quick saw table in one day reinforces these concepts in your brain and gives you a great workshop accessory. It will also introduce you to the basic ideas behind the Windsor chair deck. I used pine for the top and oak for the legs. You can use other species, but I recommend a soft species for the upper body and a hard species for the legs. The top is 2″ x 71⁄4″ x 17″. Cut the four legs into 13⁄4” x 13⁄4” x 22″ and make them into octagons, using a plane or your table saw. the legs so they are 11⁄4” square at the top. Thread the tenon with a knife or you can do this on a lathe. Each tenon should be 27⁄8” long, 11⁄8” in diameter at the base and slightly smaller taper with a diameter of 5⁄8” at the tip.This inexpensive tool is available from Lee Valley Tools and works like a pencil sharpener.

Windsor Sawbench cutting list

No. Item Size (inch) Material twl❏ 1 Top 2 71⁄4 17 Pine❏ 4 Legs 13⁄4 13⁄4 22 Oak

Top

Use your model to position the pins on your actual saw table and draw a line of sight (64°) using the bevel ruler. Then reset your bevel gauge to the resulting 15° angle. Clip it to your line of sight and desk. Clip the 5⁄8” drill bit to the brace and position the foot perpendicular to your line of sight. Place the tip of the bit in the position of your foot mortise and the splint head so that it matches the resulting angle. Drill until the drill lead screw pokes through the other side of the seat. Remove the hole, turn the top over and complete the cut from the top of the saw table. Now drill this hole into a shape that matches the tenon. Lee Valley sells a more suitable reamer than the one that can be used in a brace, power drill or drill. Drill 5⁄8” holes until the tip of the reamer just fills the top 5⁄8” exit.

Good wood for piling furniture

Read more: How to get more candles in the resort So when I started making furniture like these wooden tables, I started with the assumption that you would buy the wood from the local lumberyard or family center. That means legs from red oak and seats from poplar. Tulip poplar is soft, cheap, difficult to spread and can be found up to 4 inches thick at most lumberyards. It is quite easy to work with hand tools and quite easy to paint. So it’s perfect for a seat or a table top. For the legs, you need something hard, readily available and cheap – red oak. You can buy tons for little cash and are available at 8/4 which is great for the footing of pile pieces. And the straight grain at the edges is more important than the grain on the face. If you can find a board with straight grains on its edges, buy it. What about humidity? If you’re working with green wood, you’ll ideally want a bone-dry base and a little moisture for the seat or top. That way, the seat will shrink in the legs and tighten the joint. If you buy your materials from a lumber mill, you may not have a lot of options regarding the moisture content of the wood. So don’t worry too much about it. Buy your red oak tree. Cut it into 24″ or 30″ lengths and let stand until you’re ready to use. You want the stock to be dry. Right before you build your staking project, buy a poplar and get to work. Whether dry or wet, everything will be fine. Just make sure your feet are in balance before you get busy, you may have other options in your area. The chair can be basswood, white pine or cedar. The legs can be white oak, maple (soft or hard), hickory, ash, or anything harder than the seat top and hard enough to knock with a mallet. It hasn’t stopped people for the past 500 years. — CS

Meeting

Assign each pin to a mortise and number the pins and holes. You want the bead’s annular rings at the end of each leg to run parallel to the bead at the top. So twist the pins to their shape until they are, and make a sign that allows you to return to that position once you’ve added the glue. an oak wedge. The kerf in each leg needs to be perpendicular to the top grain (and to the annular loops of the end grain) so you don’t split the top as you drive the wedges in. To assemble, paint the plywood surfaces with hidden glue (it’s reversible), and drive into the legs with a mallet. Then turn the saw table over. Paint the wedges with glue and nail them to the kerfs in your legs. After the glue dries, level the wedge joints. Then level the legs (there’s a short video listed below in the Online Supplement in case you need upgrade instructions). I paint my desk; They are usually covered with paint in the end because they make a great base for finishing furniture. : how to lose weight with plantar fasciitis

Last, Wallx.net sent you details about the topic “How To Calculate The Angle Of Stool Leg❤️️”.Hope with useful information that the article “How To Calculate The Angle Of Stool Leg” It will help readers to be more interested in “How To Calculate The Angle Of Stool Leg [ ❤️️❤️️ ]”.

Posts “How To Calculate The Angle Of Stool Leg” posted by on 2021-11-07 02:21:14. Thank you for reading the article at wallx.net