How To Build A Wood Boiler System

In this Alternative Heating & Supplies post, you’ll find out what are the best tips & tricks on how to build your own wood boiler and the areas of concern that should be taken into consideration when building your own outdoor or indoor wood boiler.Learn how to avoid the usual mistakes that are connected with the following boiler parts:Reading: how to build a wood boiler system

- The water circulation inside the wood boiler

- The quantity of water that is recommended to use

- The burn chamber size

- What materials to use for building your wood boiler

- The chimney location

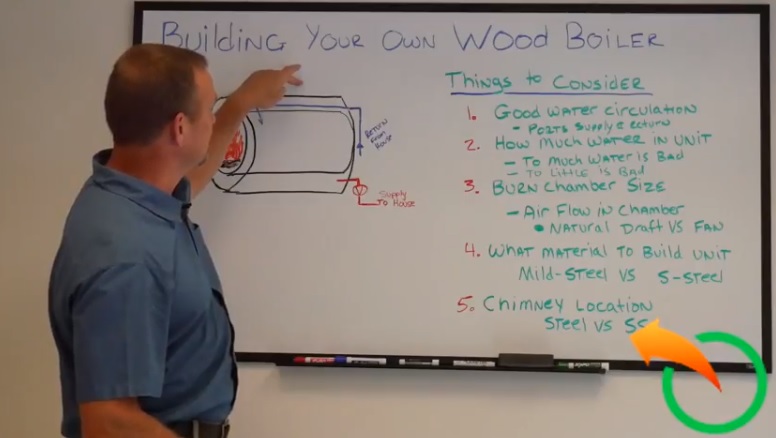

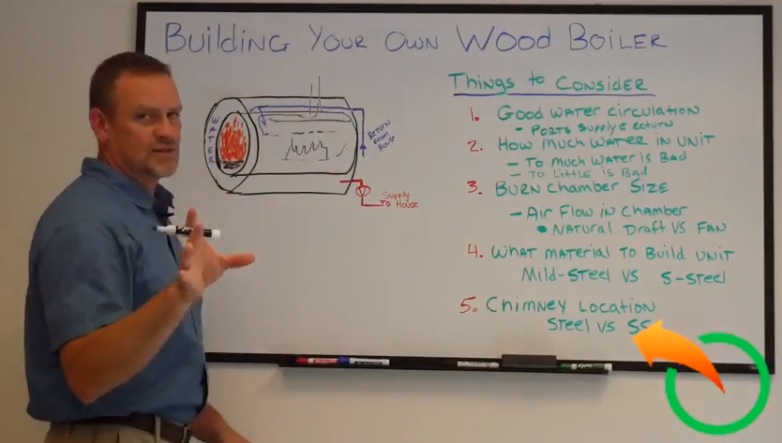

In this post, we’re going to be talking about the following wood boilers parts: the water circulation system, the ports from the supply and return going in and out of the house, and circulation inside the indoor wood boiler. That is probably the biggest mistake that most guys designing their own wood boiler make. Most people forget that the circulation inside the wood boiler is critical. How much water is in the unit is another issue you’ll learn how to solve. A lot of companies who manufacture outdoor wood boilers claim that you need 400 or 500 gallons, while others claim they only need 100.Burn chamber size is another issue, as some people that choose to build their own wood boiler units make chambers that are much too large and some make them much too small, so Alternative Heating & Supplies will help to give you an idea for sizing your indoor or outdoor wood boiler.What kind of material will be used to build your unit? Most people use large propane tanks or oil tanks and all sorts of material that you can find (or already have) and modify. So that, stainless steel versus mild steel is not really an issue.Chimney location is a personal preference, but further into this post Alternative Heating & Supplies experts share their recommendation.

Wood Boiler Building Plans

Contents

How is The Water Circulating Inside of a Wood Boiler

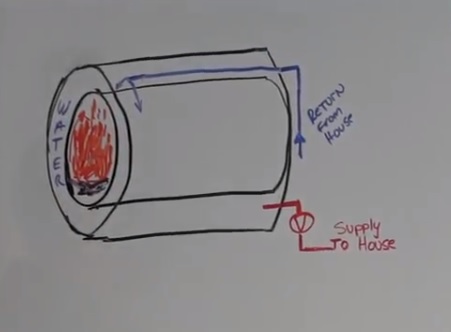

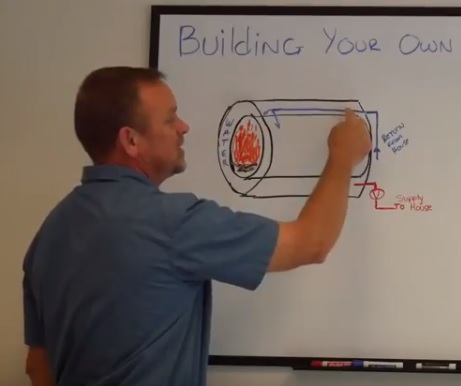

Wood Boiler Water Circulation SystemThe Water SupplyThe first thing you should consider when building a wood boiler is proper water circulation, and this means you should know where to put the ports for supply and return. Below is a drawing of a barrel and barrel style boiler and although some of you are going to opt for different styles, the concept is very similar. This example represents the most common design that people use when they are building their own wood boilers.

How Much Water is in the Unit?

This is, again, a designer’s choice, especially for those of you who are choosing leftover material – like large propane tanks or round cylinders – cutting them and cropping them to use them as a wood boiler barrel.But a lot of the name brand companies out there have 400 or 500 gallon tanks. We will be covering that aspect further on along with why you do not need so much water with your air circulation.Alternative Heating & Supplies experts recommend low amounts of water. The most efficient things on the planet are low-volume by nature. Domestic hot water tanks with fast recovery are usually 30 to 40 gallons or the most energy-efficient thing are tankless hot water heaters. No water.The most energy-efficient boilers, in-house boilers, have 7 or 8 gallons. Water is not the magic trick. Recovery on the other hand, is the magic trick.How hot and how fast you can recover from the loss of heat from heating your home is what you really want. Think of it like this, if you’re heating 900 gallons of water and not heating anything, how much energy is it going to take to heat those 900 gallons? It will require a lot of energy to just keep that water hot. If you reframe the prior and say, “How much energy does it take to heat 100 gallons?”, the answer is “A lot less if you’re not heating anything”. So, keep the water count quantity nice and low while having the recovery. The only way you’re going to know that is trial and error which, unfortunately, is it not so easy.DIY Wood Boiler Kits and PlansHere, at Alternative Heating & Supplies, we sell wood boiler kits that can help you with this process referring to doors, and solenoids, and aqua stats, to make the system work.

The Burn Chamber Size

Burn chamber size depends on how large your house is, what the burn chamber size is for and how much surface area you need to transfer the heat from the chamber to the water.Read more: how to make a pizza starPeople who have an average sized home, anywhere from 1,200 to 4,000 square feet, usually require 3 to 4 feet of burn chamber depth. If you have around 3 or 4 feet in diameter resorting to a circle, so, 3 or 4 feet deep – 38 to 48 inches in width – it should be plenty of surface area that allows you wood storage, that is what gets you the burn times. Burn times are what the point of storing wood for 12 to 24 burns inside the unit.The Air FlowThe air flow inside the burn chamber is really important as well. We have door kits that will help you figure this all out, but if you want to design your own door, you need to be sure to have good airflow inside your unit.Some people bring the airflow from the back, some people bring in from the front, some use a natural draft system, which is where you just open up a flapper and let the air flow in. We do not recommend it because it makes the unit smoke, and the fire really never gets up to temperature, you cannot burn green wood, you smoke out your neighbors, and it smells like you’re burning garbage. The reason is because you are burning a cold fire. It smokes a lot like when you’re starting a bonfire for the first time, and until that fire gets hot, you’re not going to clear up the smoke or anything else.This is where we cycle back to how much water is in the unit because if you have a natural draft system, you’re going to require a lot more water as that fire does not get hot rapidly. So you’re going to need more water to buffer that fluctuation of recovery.However, if you’re fan-induced like the doors kits that we sell, you’re not going have to worry about it, because the fan is going to blow on that fire, making that fires heat rise quickly.You will also need to get a gasification burn, and what a gasification burn is when you’re burning over 1,600 degrees, basically, no smoke comes out of the chimney. That’s what you’re trying to get to as fast as humanly possible. Yes, we’ve heard, “Well, you’re blowing the heat right out of the unit.” That’s not necessarily true if you design it properly. You’re burning the gases and if your chamber is completely submerged in water, the energy is going into the water.

What Materials Should You Use for Building Your Wood Boiler Unit?

Most people are utilize their scraps or what is lying around their yard or shop.The age old comparison is mild steel vs stainless steel. To be candid, we prefer mild steel. All the major manufacturers who are building boilers today, indoor boilers and outdoor wood boilers, are still building them out of mild steel.Stainless steel is a great product to avoid rust and scale inside your water jackets. The back draw is that stainless steel is made out of two or more different metals so when there’s fluctuation of rapid temperatures inside and outside of that burn chamber, they’re going to go from 400, 500 degrees to 1,600, to 2,000 degrees. Ideally, we want the metal to be the same material, so it shrinks and expands equally. This is the primary reason why we recommend mild steel.

The Chimney Location

Last, Wallx.net sent you details about the topic “How To Build A Wood Boiler System❤️️”.Hope with useful information that the article “How To Build A Wood Boiler System” It will help readers to be more interested in “How To Build A Wood Boiler System [ ❤️️❤️️ ]”.

Posts “How To Build A Wood Boiler System” posted by on 2021-11-02 23:25:49. Thank you for reading the article at wallx.net