How To Build A Powder Coating Booth

If you want to achieve good results with powder coating, there are a few requirements that are common to any workshop-based process, and a few things that are specific to setting up a successful powder coating shop. The difference between having and not having these things is not that you can’t do the work, or even get good results, but rather that the work is more difficult and less fun, and your results are less likely to be good.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothThis Tech Tip is From the Full Book, POWDER COATING: A HOW-TO GUIDE FOR AUTOMOTIVE AND MOTORCYCLE PARTS. For a comprehensive guide on this entire subject you can visit this link:LEARN MORE ABOUT THIS BOOK HERERead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothSHARE THIS ARTICLE: Please feel free to share this article on Facebook, in Forums, or with any Clubs you participate in. You can copy and paste this link to share: topqa.info/bodywork/how-to-create-a-power-coating-workspace/Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothThe first thing you need is a warm, dry, clean, and pleasant space to work, and that often requires a little effort. Your workspace should fit the work you plan to do as well as your own personal needs and comfort requirements. The main thing is to give yourself plenty of space for your projects and some elbowroom for yourself. You don’t want to get powder all over everything you own; or worse, things that other members of your family own! You also don’t want to knock things over or smudge your beautiful coating.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothSo before you begin, take stock of your available space. It can be as simple as a prefab garden shed from a home supply store or as elaborate as a dedicated workshop with a professional-grade oven. It might even be a patio, and depending on your local weather, that can be a great option. But most likely, it’s your garage or a freestanding workshop.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Infrastructure Requirements

Contents

The first thing to realize about powder coating is that it requires its own infrastructure. In addition to light, ventilation, and a workbench, you need compressed air. So plan on at least a small portable compressor to run your powder coat sprayer (see page 33 for more details). You also need a curing oven (see page 36 for more details).Local LawsYour local laws may have something to say about powder coating in your garage or workshop, especially if you live in an urban area. Powder coating has air-quality implications, and although there are generally allowances for amateurs, check your local laws.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothElectricity and LightingOne utility service you absolutely need is electricity. A powder coating gun, air compressor, and curing oven all need power. Plus, you want some light so you can see what you’re doing. Ideally, you have plenty of outlets to work with, and a clean, well-lit space for working. Paint your workshop floor, workbench, and walls in light colors to reflect light around the space while you work. This cuts down on shadowy places and helps reduce fatigue.You need a lot of light to have a clear view of your coating work. The general light level that you need to change spark plugs won’t do for powdering. Modern fluorescent fixtures provide a tremendous amount of light, and freestanding banks of halogen bulbs work well, too, although they tend to create a lot of shadows. Your best bet is a few four-tube fluorescent fixtures right over your work area.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothIf you don’t have access to electricity to run an air compressor, powder gun, and lights simultaneously, you have to find a power source; nothing else will do. Curing is another challenge for the power-impaired; you need 120 volts for small items and 240 volts for larger pieces.VentilationAdequate ventilation in your workspace is very important for good powder coating. You’re going to be blowing a fine powder onto your work, but enough of it ends up in the air that you won’t be able to breathe without good airflow.The materials used in the making of powder are usually toxic to some degree. You need to bring fresh air into the powder booth and evacuate the dust constantly; when curing the powder, you need to evacuate the fumes. Powder is also generally flammable, so you need to make sure that fire safety has been perfected, especially if you’re sharing the garage with your household furnace or a water heater!Once again, your best bet is to work outside, but a simple open door and box fan can keep things reasonably clear. See the instructions on pages 28 and 30 for building a powder coating booth to help keep your breathing air clean.Another tool that may help is a carpenter’s sawdust collector and extractor system. These are more expensive, but they are designed to suck up floating dust and either expel it from your shop or deposit it into a collection bag.Regardless of the air cleaning system you use, always wear a good-quality respirator suitable for painting when you are working with powder coat.Safety GearThe first items on your shopping list should be your safety gear. This includes skin and breathing protection as well as eye protection. Powder coat is wonderful stuff, but you really don’t want it in your eyes or your lungs.Get yourself a top-quality respirator. The little breathable masks they sell for painting are okay, but only just okay. You won’t want to wear them for a long time, and you’ll be tempted to go without them. If you have a good-quality respirator with replaceable canisters, you’ll feel better about wearing it. Similarly, get a good set of safety goggles that protect your eyes from powder in the air.Buy a bottle of contact lens saline solution and keep it handy in your powder coating workshop. If you get dust or powder (or anything else) in your eyes, it’s right there to flush out the foreign matter.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothAnother key safety item is work clothing. This keeps cleaning solvents and powder off your skin. You can get a box of nitrile or latex gloves to wear. Don’t worry about changing them frequently and you don’t need to invest in a set of nicer mechanic’s gloves. Old pants and long-sleeve shirts are best to keep your skin clean, and a shop apron or shop coat is even better. Finally, a hat that covers all or most of your hair is a good investment.A welder’s bandana is shaped to tie around your head and keep your hair out of your project. These are inexpensive and work very well.Of course, you also want a handy first aid kit. Even if you are always careful, it is wise to have some burn treatments ready. Similarly, you want to keep a good fire extinguisher (or two or three) around your shop, just in case.Finding (or Building) a Good WorkbenchWorkbenches are an absolutely critical part of your workspace. You do a lot of careful work on a bench, so you want to be sure that it is at the optimum height for you (or whoever will be working there). Obviously, the optimum height for someone who is 5-feet 2-inches tall is different from the height for a 6-footer, so spend some time testing benches of different heights to find what works best for you.Remember that you will work on some items from the top, and some from the sides, so you may decide that what you really need are a few different-height benches for different purposes.Another important factor for workbenches is that they have to be rock solid. A wobbly bench is no bench at all. So make sure that your bench is heavy, attached to the wall, and solidly standing on the floor. Most workbenches are built in place for precisely this reason. As nice as a premade bench looks, they are generally lighter and designed to stand free. Unless they are well attached to a wall, they may move when you don’t want them to.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

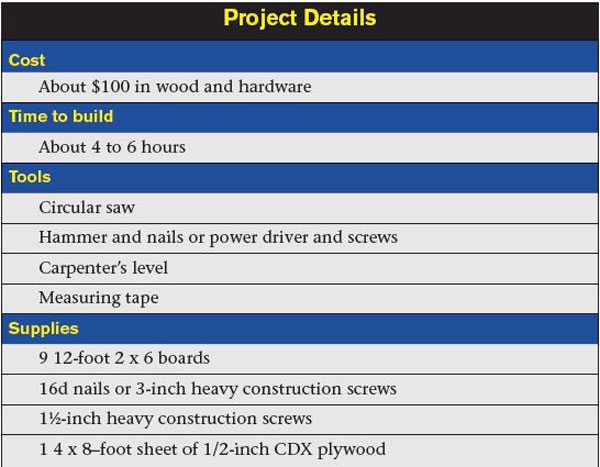

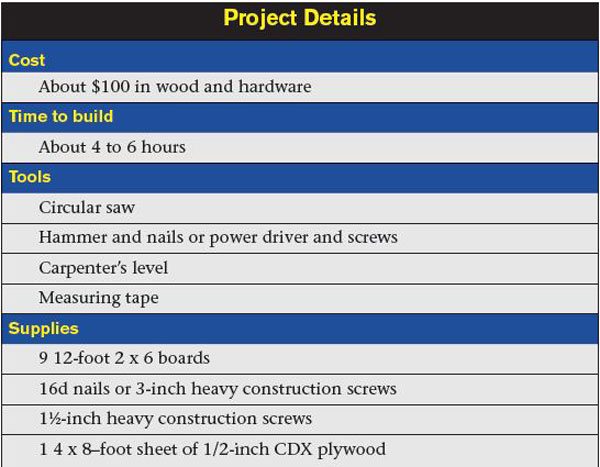

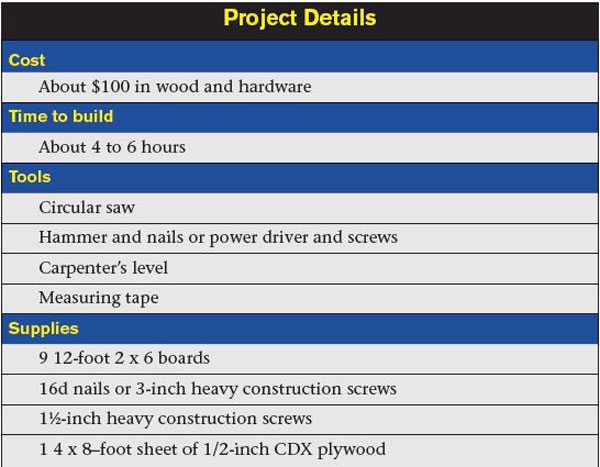

Project: Low-Cost Heavy-Duty Workbench

The classic workbench is a heavy-duty item, built in place and securely mounted to the wall. This kind of bench is great for mounting tools, such as a drill press, bench grinder, or hydraulic press, and it’s also a great place for general tasks.This project uses inexpensive 2 x 6 stud lumber and some 1/2-inch plywood for the benchtop. It is painted white for good light reflection and a clean look. Brand-new white paint at very low cost is often available at a recycled building supply center.This benchtop is 42 inches above the floor, which is a good height for a tall person, but likely too tall to be comfortable for shorter people. In general, 36 to 40 inches is a good height. If you are tall enough to use a higher benchtop, you can put a large storage shelf or set of cabinets under the bench.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Protect Your Surroundings

If you’re like most people you don’t have a separate space in which to undertake powder coating, or to handle cleaning and prep. Preparing for powder coating and then performing the work is a messy business, with lots of dust and overspray involved.At a minimum, you want to cover absolutely everything in your garage or workshop with plastic drop cloths. These are inexpensive at a home supply store, so buy more than you think you need. Be sure to tape down the edges; powder has a way of getting on everything in the vicinity.If you’re working in the same garage that houses a car or your home’s laundry facilities, you need to be extra careful to protect the areas and items you don’t want to powder, or better yet, move the project out of that space entirely.Building a Powder Coating BoothPowder coating is a fairly messy proposition because you’re using a compressed-air spray gun to deposit the powder on a charged metal item. Just like using paint, your powder is going to get into places other than the intended surfaces. Because you’re likely working in a space shared with other purposes, you need to control that overspray. The main point is to keep the powder dust from getting all over everything, which happens if you don’t separate your powdering area from the rest of your shop! Overspray when powder coating is simply a reality you will have to manage.The best thing you can do is to perform your spraying outside. Even then, it’s wise to be cognizant of what’s downwind. However, for many of us, through many months of the year, working outside is just not feasible. In that case, your next-best option is to create a powder coating booth, or several booths, for work of different sizes.

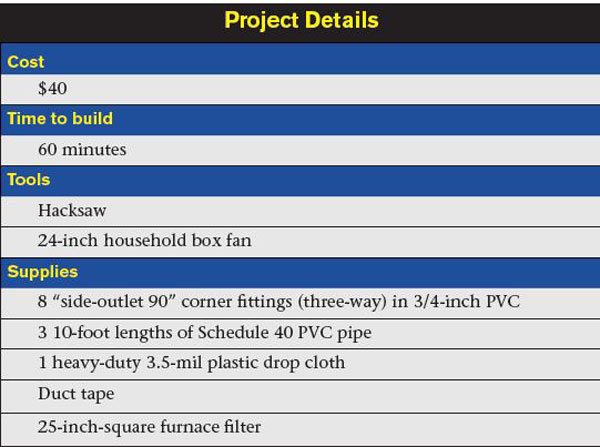

Project: Benchtop Powder Coating Booth

A simple benchtop box is suitable for powder coating smaller items up to 25 inches on a side. The size is equal to the amount of space in a standard kitchen oven, which is what most of us use for curing the powder.This project was built using 3/4-inch Schedule 40 PVC pipe and fittings, plastic sheeting, a standard household furnace filter, and a basic household box fan. You can assemble this structure with PVC cement and make it more or less permanent, but the pieces hold together just fine without the cement, and then you can disassemble the whole thing quickly. Also, changing the size of the box is simply a matter of cutting the pieces of PVC pipe to the desired length.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

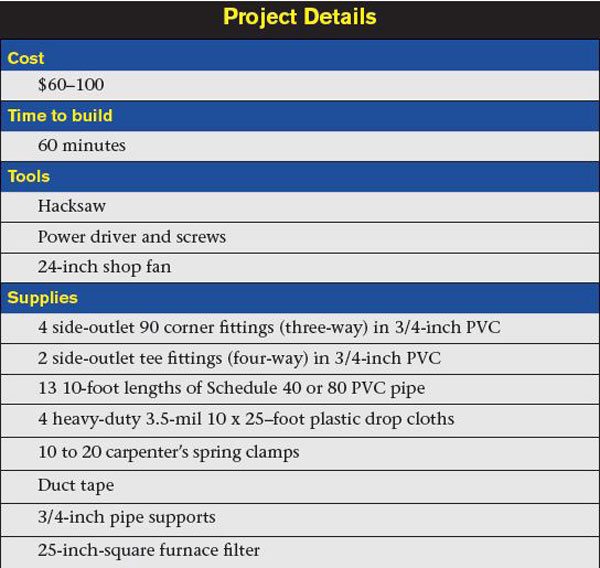

Project: Large Powder Coating Booth

This project creates a simple and lightweight powder coating booth suitable for coating larger items inside your garage or workshop. This booth is certainly suitable for shooting a coat of powder on any part, especially those that you need to walk around to give full coverage. The best part is that it is very easy to put up this hanging-curtain booth and take it down again later. You get protection while you’re blowing powder and it doesn’t take up your space permanently!This project specifies 3/4-inch Schedule 40 PVC pipe because the example shown here was built in a workshop and was well supported from the ceiling, but you could use Schedule 80 PVC, thin-wall metal conduit, or even metal fence pipe of the same outer diameter for more rigidity to build the project as a standalone. Be sure to weigh down the legs with concrete construction piers if you build outside, though!Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Compressed Air

Powder coating requires compressed air at about 5 to 10 psi; that’s not much when most compressors are designed to deliver air at approximately 90 psi. You’re going to need a low-pressure regulator with any compressor you buy. These can cost from about $20 to well over $100. You can use a less expensive model that adjusts down to 5 psi, but these are often less accurate in their pressure delivery. Use a pressure gauge to ensure that the pressure is not too high.A much bigger decision is what kind of air compressor to get. If you don’t already have one, you have some shopping to do. If you’re thinking strictly about powder coating, you can buy a small compressor that can fit under the workbench. These are affordable, they work great for light duty, and they plug into a standard 120-volt outlet.Small compressors are fine for powder coating, but they can’t do much more than fill a tire, use an impact wrench, or run a spray gun on a light-duty cycle. It’s not realistic for one to power a blast cabinet for parts cleaning or something big such as a tire-mounting machine. Getting a larger compressor involves more expense and work to install it in your garage, but if you plan (or hope) to use more serious tools, you’ll never look at your big compressor and wish you’d bought something less powerful.Compressor SizeThe first step is to figure out how much compression you really need, and then get a compressor that comfortably meets your needs. To figure out the size and power of the compressor to buy, look at the cubic feet per minute rating (CFM) and the maximum pressure in pounds per square inch (PSI). This figure is usually printed on the compressor and should be included in the machine’s advertising and literature. In addition, look at the tools you want to run and think about how frequently you plan to use them.When you go compressor shopping, you will notice right away that compressors are frequently rated and sold based on their horsepower, which is a misleading statistic. Bear in mind that the CFM ratings assigned by the manufacturer are generally optimistic. Moreover, the claimed rated CFM is actually the amount of air that the compressor sucks into the intake to be compressed, not the amount of air that comes out of the hose.You must also understand that the air usage requirement for most tools assumes a very light-duty cycle, which is to say, perhaps using air only 10 to 15 percent of the time. You can then see that if the compressor manufacturer is overstating the machine’s ability to produce compressed air, and the tool manufacturers are understating the amount of air they actually need if you plan to use them intensively, you need some “overkill” on your compressor.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothYou should choose a compressor for your maximum needs. A free-standing abrasive cabinet designed for home shop use can require as much as 10 to 15 cfm at 80 or 90 psi. That calls for a 240-volt, belt-driven, 3.5- to 5-hp, 60-gallon vertical tank compressor, which you can get for about $400 at any home supply big box store. However, if you’re just planning to use your powder coating kit and an air nozzle to blow out dust you can be perfectly happy with a 120-volt, 4-gallon, “hot dog”-style unit producing 3 cfm located under your workbench.The bottom line is this: For any kind of serious automotive work with air tools, and absolutely if you’re running an abrasive blast cabinet or other freestanding tool, you need a 240-volt compressor pumping more than 10 cfm with a tank of at least 60 gallons. When it comes to air power, buy as much compressor as you can comfortably afford and store in your shop. You will never regret going large.A bewildering variety of compressors are available, but it’s easy to choose a good one. Look for a recognized name brand with solid construction in the compressor machinery. These cost a bit more, but it is far less than replacing a cheap compressor every few months.Compressor LocationThe appeal of a small compressor is that it doesn’t take up much valuable working space. But even if you have a big compressor, you don’t have to let it dominate the garage. Compressors are noisy, so they are often placed outside the shop in a protected shed or in a well-insulated closet inside the garage. As long as the compressor’s heat can’t build up around it, an isolated space is great for a compressor.All things considered, the best place for a compressor is outside. But a compressor is an expensive piece of hardware, so it has to be protected from the elements. A simple shed does the trick nicely. Plumb the air lines through the wall into your shop and leave the compressor on, or install a switch for it next to the shop’s light switches. That way, you can fire up the air at the same time you turn on the lights.One word of caution about putting your compressor outside: You might annoy your neighbors if it’s a noisy unit and you use it a lot, especially if you like to work late into the night or if you leave it turned on and it roars to life at 3:00 am. If your garage is near your neighbor and you want to put the compressor out back, be sure to build its shed with some fiberglass insulation to reduce the noise.Air Line PlumbingThe easiest and cheapest air plumbing you can have is simply to attach the air hose to the compressor and coil it neatly when it’s not in use. Just make sure that your hose reaches anywhere you want to work, including through the door of your shop and into the parking area.For an upgrade to the coil of hose on the floor, consider a hose reel. Even shops with a full hard-line air plumbing system often use a hose reel. This is simply 50 or 100 feet of quality air hose wound on a big spool. A connection is at the center to allow the reel to spin, and then a length of hose connects the reel to the compressor or air system. When you need the hose, just grab it and pull and then crank it back onto the reel when you’re done.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothOne expense that’s worth the money is buying quality air hose. It will last for years or even decades. You can run over it with a car or brush it across hot metal and it takes the abuse. Avoid the coiled plastic air lines that are sold in bargain stores. That material is easily cut, burned, crimped, and crushed, and the end fittings often come loose. The exception is that you might want to have one or two cheap plastic hoses to use for jobs that you know might damage your good air hose.Quick-Release ConnectorsA question that everyone faces is what style of quick-release air connectors to use. Once you choose a style, you’re locked into that style unless you replace all your connectors, so it pays to choose wisely. There’s really only one good choice, and that’s the standard Industrial Interchange style; it’s the most common. Chances are, if you buy or borrow an air tool and it has a quick-release plug on it, it will be an Industrial Interchange style, and the same is true with other air sources.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothEven within the Industrial style, there are substantial differences among fittings made by different manufacturers, and they don’t always work well together. Failure circumstances range from a little extra air leaking to the connection popping apart randomly. If you’re just starting out with compressed air, buy a lot of couplers and a lot of plugs from the same manufacturer all at once, and use them for as long as possible.The Industrial Interchange plug goes by various names, including Standard and Type D couplings, but if you look for 1/4-inch NPT plugs manufactured to military specification Mil-C4109, it’s the right part.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Types of Curing Ovens

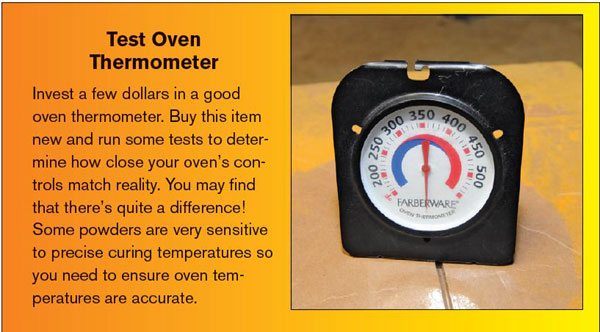

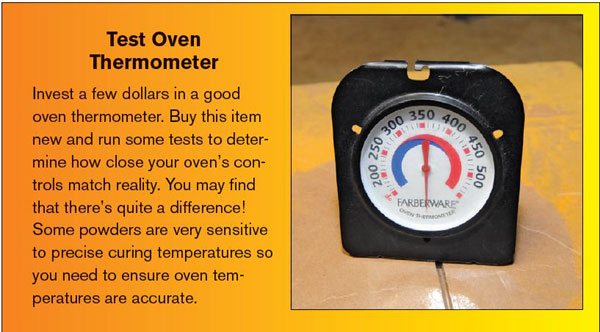

One fact you can’t avoid in powder coating is that you need a heat source to cure your parts. The least expensive way to handle this is with a standard kitchen appliance. You can use a toaster oven for small parts, and a standard kitchen oven for items up to about the size of a steel automobile wheel. Beyond that, you have to look at an infrared curing station or send your work out to an industrial powder coating shop for curing. Professional cooking ovens (such as commercial pizza ovens) are fantastic if you can find one, but they are generally too large and expensive for home use.Is it okay to use a gas oven? In this section, I mostly discuss electric ovens. That’s because you cannot use a gas oven safely with powder coat at home. Loose powder has the potential to burn and cause a fire if exposed to open flame, so it’s important to stick with electric.Toaster OvenA basic toaster oven handles small items, and has the advantage of being conveniently sized and extremely inexpensive. You can pick one up at any thrift store or garage sale in good condition for just a few dollars.Buy the largest toaster oven you can find, and make sure that it comes with controls for baking. It must have a heating element below the rack and a temperature control. A “light to dark” knob doesn’t give you the temperature control that you need over time.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Curing Techniques

If you plan to coat larger items occasionally, you may be able to do your own coating and then send the items to a professional powder coating shop for curing. Ask around. Many shops may decline to cure items they haven’t coated, but some may take the work.The real challenge in coating something yourself and then having it cured elsewhere is getting it from your shop to the curing oven without destroying or losing the powder. Once the electrostatic charge is turned off, the powder is just staying on your part because that’s where it was applied. The slightest touch, a breeze, a rain-drop, or just about anything disturbs the coating and rubs the powder off.Unless you have a really good way to move the part to the curing oven without touching it or exposing it to wind and weather, it’s generally a good idea to coat it and cure it at the same location.Infrared CuringOne solution to the problem of curing oversize parts is an infrared curing setup. This is a set of infrared heat lamps that are usually articulated to allow you to position them around the part. You are likely to have to perform your curing in stages, and move the part or the lamps to get a good cure on every section of the project.A set of infrared curing lamps cost about $500, but low-power 1,500-watt units can be obtained for as little as $199. They all plug into a standard 15-amp household outlet, but you may want to plug different lamps into different circuits if you’re using more than one.You need some space to set up infrared curing, even though the lights are designed to be placed just inches from the part to be cured. The lamps generate a lot of heat, so they need to be kept well away from cars, free powder, solvents, and pretty much everything you don’t want to cook. You must pay attention to what’s above the lamps as well as what’s around and below them. Heat rises and you run the risk of fire if you’re not fully aware of the area surrounding the infrared lamps.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothGetting an even cure on all sides is critically important to getting good results. You have to move the part around to get it to cure evenly on all sides, so be careful not to disturb the powder distribution as you do so. If possible, try to move the lamps instead of the part to avoid damaging the uncured finish.You can buy an infrared thermometer at any hardware store. This little device doesn’t cost much and is a super addition to your powder coating kit, whether or not you buy infrared curing lamps. It is also handy to ensure that heavy pieces have come fully up to temperature in the oven. You simply point the thermometer at the piece, pull the trigger, position the dot of laser light on the surface that is curing, and read the temperature on the back of the gun.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Project: Outside Oven Installation

One thing to think about as you install a powder curing oven is that the baking process is going to produce a small amount of fumes that you really don’t want to breathe. If at all possible, you should move the baking oven outdoors. Keep this change in location in mind when you create the power circuit. Most kitchen ranges have a 4-foot cord; you can buy a 6-foot cord, but that’s the longest cord available.The best solution is to put your outlet near a door or window. Set the stove just outside and run the cable through the door or window when you want to use the oven. This allows you to create an easier wiring plan and save some money on a weatherproof outlet. You can unplug the oven when you’re not using it. If this isn’t possible, you may have to create an outdoor outlet for the oven.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Project: 240-Volt Range Outlet Circuit Installation

This project shows you how to wire a new outlet for a standard 50-amp 240-volt kitchen range with 6/3 NM cable. This cable has three insulated wires. Black and red for hot, white for neutral, plus an extra, uninsulated copper ground wire.For this project, I assume that you have a main circuit panel or sub-panel in your workshop or garage, and that service is activated. If you are building a new shop or garage, you must have a service panel in the shop before starting this project.The big advantage with NM cable is that you don’t have to buy and install conduit (which also means you don’t have to bend conduit and attach corner pieces). The electrical code allows you to simply drill holes through studs and route the flexible NM cable through the holes to your fixtures. Plus, the junction boxes and outlet boxes can be plastic because NM includes its own ground wire.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Curing Racks, Supports and Hangers

The process of curing powder coating means that the powder melts and flows together to create a strong finish. So, it stands to reason that when you place the item in the oven, you cannot just set it on a pan or a grille. The part would end up being glued to the pan and, worse, the finish is damaged. Therefore, you need to create supports to hold the new finish off the hot surfaces in the oven while it cures.In most cases, you have at least one side of any powder coated piece that isn’t coated, or it’s already cured and you can set it on that side. But you may need to support or suspend a part in a way that gravity doesn’t assist you, and that’s why you end up making all kinds of tees, jigs, threaded stands, and hangers to suspend pieces in the oven.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothYou also have to create similar stands and racks to use to shoot the powder evenly on the parts. Spraying stands may be made of wood, cardboard, Styrofoam, or whatever you have on hand. But the curing stands must survive oven temperatures. That limits you to metals and ceramics, because the 400 to 450 degrees F required to cure most powders will set wood and paper on fire and melt or ignite plastics and petroleum-derived materials.As you take on different projects, you need to create some custom oven supports, so start thinking now about the materials and shapes you’re planning to coat and how you might support them in the curing oven.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Project: Custom Oven Stand

This project creates some generally useful stands and racks for curing powder coated items. Be aware that you might need to make custom stands or hangers for any particular item you coat, but if you have a good selection of the basics, you’ll know when you need a custom stand, and you’ll have a good idea of how to make it. For this project, I picked an actual powder coating problem that I faced in the course of research for this book.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

Powder Coating Equipment

In addition to the powder coating kit, oven, and air compressor, a number of tools can help you get good results from your powder coating efforts. These begin with safety gear and parts cleaning tools, which are important and necessary. In addition, general modification and fabrication tools always come in handy.Parts Cleaning ToolsYou want to obtain at least one automotive parts washer, and probably two. With two washers, one can stay full of water and a detergent-based cleaner while the other remains filled with a solvent-based cleaner such as mineral spirits.If you want to get serious, a conventional household dishwasher makes a great parts washer, combining heat and detergent. But this requires additional plumbing and environmental considerations.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothRead more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating booth

- Drill press

- Angle grinder with wire cup brush

- Angle grinder with metal grinding disc

- Bench grinder with wire wheels

- 120-volt wire-feed welder

- Bench vise

- Variety of pliers, locking pliers, and cutters

- Blower attachment for your compressor

- Shop vacuum dedicated to the blast cabinet, and another vacuum for cleaning up powder overspray

- At least one fire extinguisher

You can add even more tools, of course. Every workspace is different and has different needs. The good news is that you can build up your inventory over time. Garage and estate sales, thrift stores, and used tool stores can help you get your shop together without breaking the bank.Read more: how to take a screenshot on galaxy s5 activeRead more: how to make your own brake linesReading: how to build a powder coating boothWritten by Jeffery Zurschmeide and Posted with Permission of CarTechBooks

GET A DEAL ON THIS BOOK!

GET A DEAL ON THIS BOOK!

If you liked this article you will LOVE the full book. Click the button below and we will send you an exclusive deal on this book.

Last, Wallx.net sent you details about the topic “How To Build A Powder Coating Booth❤️️”.Hope with useful information that the article “How To Build A Powder Coating Booth” It will help readers to be more interested in “How To Build A Powder Coating Booth [ ❤️️❤️️ ]”.

Posts “How To Build A Powder Coating Booth” posted by on 2021-10-23 11:25:11. Thank you for reading the article at wallx.net

GET A DEAL ON THIS BOOK!

GET A DEAL ON THIS BOOK!