How To Make A Custom Wide Body Kit

OK Guys You’ve been asking for this for some time now so I decided to get my act together and compile what I think is the most thorough how to guide on creating wide-body kits and using epoxy putty that you are likely to find anywhere. Big call perhaps but instead of carrying on (ooops, too late) I’ll just get straight into it and let you decide for yourself…Today’s post is brought to you by myself (clearly) and the ever talented Mohammad Kemal Efhard ( @iamefhard ) who has kindly agreed to share some of the process shots from a recent Rocket Bunny inspired custom Ferrari that he built…among the many others he has made wearing the familiar bulges of the rocket powered bunny. But before we can even start to think about the Bunny we need to get familiar with the stuff it’s made of…Reading: how to make a custom wide body kit How To Work With and Use Epoxy PuttyThe process of working with epoxy putty is the same regardless of how it is used but note that this guide was written for a build requiring putty to smooth out and hide a join between castings.

- I use Milliput brand Epoxy Putty and recommend it highly. I also have a glass of water handy at all times when puttying.

- I mix the two substances supplied in an even 50:50 ratio until the two colours (yellow and white) are one consistent colour (as shown in image above)

- I then take as much as I need and apply it to the applicable area.

- I have a few shaping and moulding tools but in most cases find my finger is far more effective at getting smooth lines and perfect transitions between panels.

- The water should only be used once you have the putty in place and or when you want to clean your fingers of the excess putty that can sometimes build up on them. Overuse of the water will start to change the properties of the putty and make it too difficult to work with as it no longer wants to adhere itself to the diecast casting.

- Look at your work from every angle possible and make sure there are no indentations or bulges in the putty work you have just done.

- One thing I find helps is to apply more than you need initially as apposed to trying to be exact. As you scrape off the excess and push it around with your finger(s) you will find the putty compressing nicely, thus removing any and all chance of ghastly depressions ending up in your beautiful custom.

Paint Stripper, Epoxy Putty and Lessons Learned

Contents

One of the questions I get asked is whether you can apply paint stripper and other toxic chemicals to your custom hot wheels after you have applied putty. The concern here of course is whether the paint stripper will damage or eat into the hardened epoxy putty and although I can happily put that concern to rest by assuring you that this is not the case, I do have to be the bearer of bad news and say STRIP THE PAINT FIRST!The reason I say, no scream this is because if you look at the custom below (of which you can see the full build HERE) you can see that my smooth transition across the bonnet is broken where the paint underneath stripped off. Now my custom forever has a line across the bonnet where the join is far from flawless. D’OH!

How To Make A Rocket Bunny Kit for Your Hot WheelsI would now like to introduce Mohammad Kemal Efhard aka @IamEfhard (follow him – we can wait) who has kindly agreed to share the Work In Progress (WIP) photos from a recent Wide Bodied Rocket Bunny Ferrari he built. Due to the language barrier I have provided the instructions and commentary that go along with the images – although it has to be said that Mr Efhard has done such a thorough job of documenting the process in pictures that most of the explaining was already done. Nice one brother! Respect.Today we are going to learn how to make something like… say, THIS! ????

Moulding a Rocket Bunny Wide-Body Kit

As far as TOOLS REQUIRED you are going to need the following items:

- Two part Epoxy Putty (d’uh)

- Metal files – I use small ones (like emery boards – the paddle pop stick looking things chicks use OK sheesh) and I have a range of different grades and widths. The more options you have here the better off you’ll be basically. Got it? OK good, moving on…

- Water (as discussed in the initial guide to using epoxy putty)

- placeholder

STEP 1

The first thing we need to do is create our flared guards – which at this initial stage look more like little cocoons – or rabbit droppings (take your pick).

STEP 2

Now we need to stick them on to our Custom Hot Wheels WIP.The putty will naturally adhere itself to the diecast casting and as illustrated by the image above is extremely maleable (moulds easily) and yet maintains a smooth and firm shape. Keep in mind that this is only the case for about 15 minutes or so – so no dilly dallying!

STEP 3

Step 3 involves patience. And tea, lots of tea. Because now we wait.

STEP 4

Once the putty has hardened it is time to go to work with our file(s) and start to give life and shape to our Rocket Bunny and/or generic Widebody kit. Note that this is one of those skills that really does improve with practice and time. I will share some of my first attempts in an upcoming post but needless to say they look more like steaming piles of … than widebodied custom hotwheels! Obviously some will pick it up faster than others (’tis the nature of life) but regardless – you keep working with the putty and file and soon you too will be creating epic creations up there with the likes of customisers like Pisut Masanong (to name but one of the multitudes of skilled customizers out there)Read more: how to apply lashes without glueWhen filing away the guards the key thing to remember is BABY STEPS. If you take off too much you’re screwed – basically, so ensure even and clean lines by working very lightly AND only doing small sections at a time. It’s also helpful to hold the car up to your eyes every so often and look straight down and across it so as to ensure the lines of your filing are evenly distributed and balanced.DO NOT try to file around the entire guard in one movement – rather keep the file as flat as possible and try to maintain this as you go. DO NOT push too heavily when filing as you instantly lose the sensitivity needed to maintain even and smooth lines.*And always be aware of your file because the last thing you want to do is be filing away whilst the other end is inadvertently filing away a much needed section elsewhere!

STEP 5

Step 5 is really just more filing. I could have called it step 4 & a bit or something but more steps makes it look more impressive so … so.. so there!

STEP 6

Now that you have shaped your wide body rocket bunny kit it is time to paint

STEP 7 – Bonus Bits

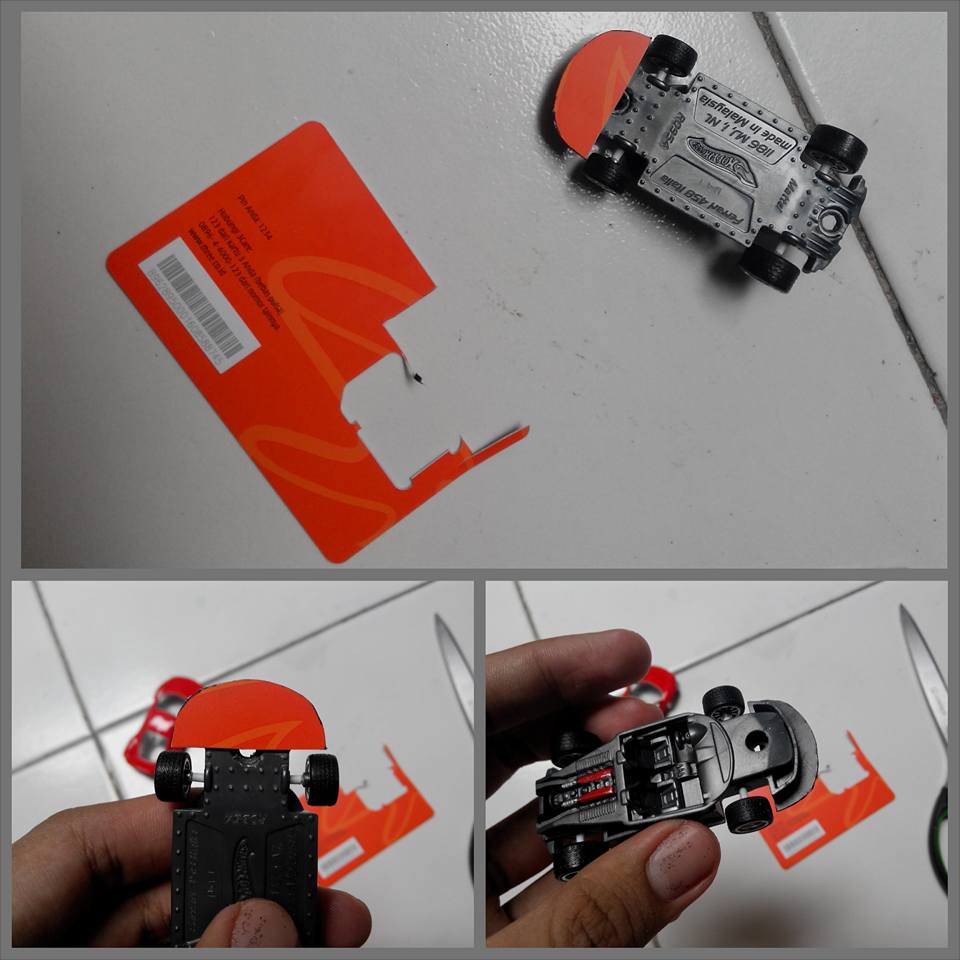

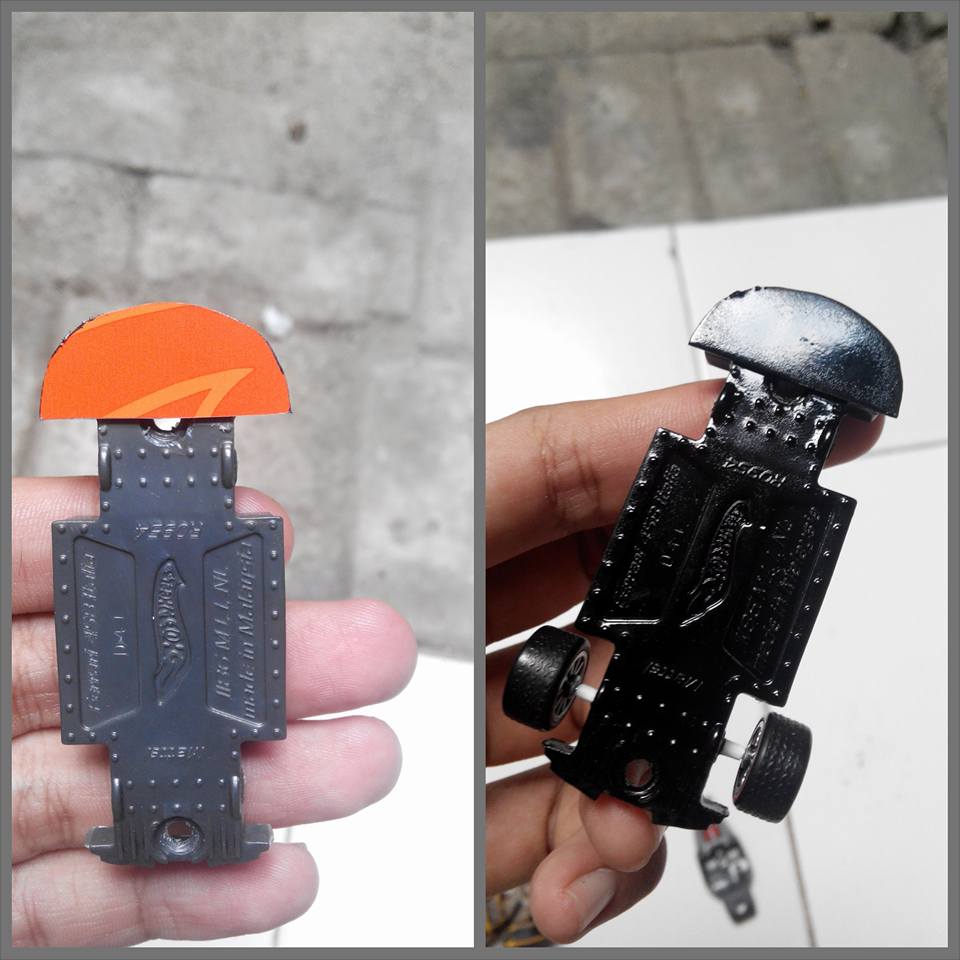

Seeing as your new custom Hot Wheels build now has a much wider stance it is only fitting that the underbody is modified to match. This of course involves actually extending the base out, which at first glance seems impossible… Unless you’ve got some expired credit cards or membership cards lying around…

Step 8 – Final Touches

Now it’s time to put your custom back together and add any Hot Wheels Decals and other racing livery you might want to add.

Where There’s 1 Bunny There’s ALWAYS plenty more.

There are actually a tonne of awesome customs already posted on the many YOUR CUSTOM HOTWHEELS posts so to attempt to bring them all over here as well would be, well it would be time consuming is what it would be and I ain’t bloody doing it!What I do have however is a couple of customs that just happened to be published on My Custom Hotwheels Facebook Group around the same time I was putting this post together.This first one comes to us courtesy of Mohd Azwandie Hussain and is another exquisite example of how awesome epoxy putty is.

Comments

commentsRead more: How to mute the teacher on google meet

Last, Wallx.net sent you details about the topic “How To Make A Custom Wide Body Kit❤️️”.Hope with useful information that the article “How To Make A Custom Wide Body Kit” It will help readers to be more interested in “How To Make A Custom Wide Body Kit [ ❤️️❤️️ ]”.

Posts “How To Make A Custom Wide Body Kit” posted by on 2021-10-30 16:55:24. Thank you for reading the article at wallx.net