Why is soldering not good for fixing cars

Video Why is soldering not good for fixing carsMost individuals wouldn’t imagine how controversial this subject nonetheless is. Ought to I crimp or solder this connection? Ask this in any discussion board and also you’ll discover opponents prepared to passionately debate the subject to demise.On one aspect you’ll discover those that will shortly crimp a connection with out giving it a second thought and go on with their day. On the opposite aspect you’ll discover these more than pleased to name the primary group “hacks” or lazy. They may insist {that a} soldered connection is rather more dependable and has higher efficiency. However who is true? The reality of the matter isn’t that straightforward. This gained’t settle the crimp or solder dialogue, however it should present worthwhile perception.Reading: Why is soldering not good for fixing cars

To Crimp or Solder, That’s the Query

Contents

Whereas it might be painful for some individuals to listen to, the fact is that within the automotive business this has way back been settled. The gold normal is to (correctly) crimp wires the place doable. That is what business does, and what you need to do, too. Whether or not you’re splicing or attaching a terminal makes no distinction. To confirm this simply have a look underneath the hood and also you’ll discover lots of of crimps, however just about no soldering. So long as you have got the precise instruments, crimping is the best way to go.Personally, I used to crimp after which solder my connections considering I used to be doing myself a favor reliability-wise. I by no means actually thought of whether or not it was higher to crimp or solder. Then I had a couple of electrical issues on some customized programs. They have been on account of wires breaking on account of wire fatigue from regular bending and vibrating, mixed with corrosion. Simply tugging on the connector you might break off the few strands nonetheless holding it collectively. And this was on a rigorously tinned, crimped and soldered reference to a high quality wire. Warmth and humidity performed an enormous issue, although. After not insignificant analysis, it shortly turned clear that there are many explanation why you shouldn’t be soldering on automobiles.Notice: The next focuses on wiring or terminal connections for automotive functions – particularly automobiles, bikes, electrical automobiles, marine, and so on. Functions that are topic to vibration, warmth, motion, thermal shock or comparable challenges. Remember that this doesn’t apply to circuit boards or different circumstances the place the wires are immobilized.

Why is Crimping Higher than Soldering?

Crimping is the method of making a everlasting electrical connection between a number of conductors and a crimp terminal in any kind. Since crimping was first launched within the Forties, it’s made itself a staple in any meeting plant. It’s fast and simple to do, much more so than soldering. It nearly feels too straightforward, which is why some individuals really feel prefer it’s the lazy solution to do issues. However absolutely simply carelessly clamping down a terminal on a wire can’t present a safer connection than a terminal lovingly hand-soldered by a cautious DIYer? Right here’s a couple of explanation why you need to take into account whether or not it’s extra acceptable to crimp or solder.

Wire Fatigue

The principle difficulty is wire fatigue. With crimped connections, the wire is free to maneuver at its leisure. Copper is pretty versatile when finely stranded, which is nice in a vibration-happy atmosphere like subsequent to a operating engine. The crimp is designed to carry the wire securely, whereas additionally permitting it to maneuver.If you solder the wire (both earlier than, after or as an alternative of crimping), except rigorously performed, the wire stiffens. It’d occur on account of extreme warmth nevertheless it primarily occurs because of solder getting underneath the insulation by capillary motion. In the event you apply warmth too lengthy (utilizing too small a solder iron), it’s just about unavoidable. For soldering newbies it’s even worse, as they have an inclination to use an excessive amount of solder to start with.One other issue when selecting to crimp or solder or automobiles is the repetitive wire motion. When solder will get previous the insulation, the wire loses flexibility. Simply attempt bending a soldered wire splice to see it for your self. In the event you set up it on a automobile, each vibration is like bending the wire somewhat bit. Finally the cables shear off little by little till there’s nothing various strands holding it collectively. Because the cable’s efficient diameter reduces, the intermittent failure points begin popping up. Lastly, the solder-reinforced wire fails.That is even worse on bikes, because of their diminished weight and excessive vibrations. Moreover, its wiring is usually uncovered to excessive warmth and to the weather (learn water) which compound the difficulty with accelerated corrosion.

Resistance

At a primary look, it’d look like soldering gives a decrease resistance than crimping. Surprisingly, actuality differs. A correctly crimped connection truly creates a metal-metal colloidal bond on the floor between the wire and the terminal. This makes it successfully fuel tight, stopping oxidation contained in the joint. The copper-on-copper connection is usually superior to solder contemplating that almost all solders have extra resistance than copper.In follow, the distinction in resistance between both strategies (correctly performed) is past the accuracy vary of common multimeters. Therefore, the distinction is negligible, particularly when engaged on 12v circuits. By that my level is that soldering won’t present “better conductivity”. When you see the cross-section of a correctly crimped cable, the place the person strands can hardly be distinguished, it’s straightforward to know why.

Give Crimping a Likelihood

Read more: Why is nezuko immune to sunlightI’m positive that a lot of you’ll like to name BS and inform me how they’ve used X technique for years with out ever having an issue. They’ll simply crimp or solder relying on in the event that they really feel prefer it or not. Heck, I’d most likely even agree with them that what they did was good, of their state of affairs. Nearly any soldered joint will final perpetually if performed proper and pressure relieved – that’s the important thing. Nonetheless, none of that takes away that on a automobile, an honest crimped connection will reliably be much less problematic than an honest soldered one. You might disagree, however this can be a well-settled reality.That doesn’t imply that soldering doesn’t have its place. For light-duty, low present duties, or the place crimping isn’t viable, soldering nonetheless is a worthwhile possibility. An ideal instance is any circuit board. It’ll merely require additional care and a focus to do proper. However for all the pieces else crimping ought to be the default alternative.

How Do I Correctly Crimp a Connection?

So that you’ve made it this far and, although skeptical, you’re prepared to offer it a attempt. Downside is, you’ve by no means given crimping a second thought and at all times used the chintzy software that got here together with your $5 equipment. No directions got here with it (after all), so that you discovered as you went. However, what’s the precise solution to do it?

Instruments and Supplies

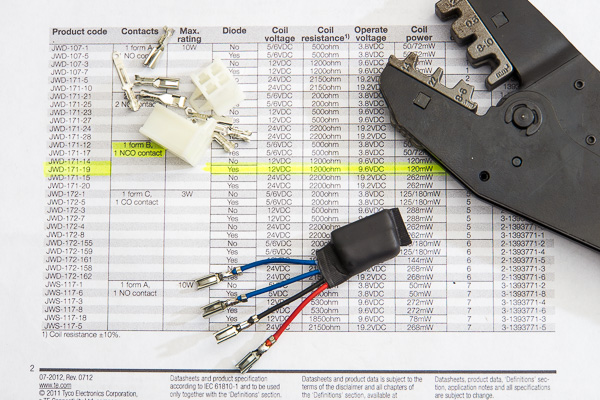

Any mission begins with the correct instruments and supplies. On this case there are a number of concerned.WiresNo matter if you happen to’re going to crimp or solder, it’s essential to choose the correct wire. Don’t underestimate its significance or complexity. There are a frightening quantity of wire qualities and specs for various functions. That features each the sheathing (PVC, GXL, SXL, TXL…) and the conductor itself (copper, copped-clad, and so on…). Click on right here for a fast overview. Select the precise wire gauge relying on its size and present draw primarily based on a amps-gauge chart.Oh, and by the best way. Don’t decide a wire’s gauge by its outdoors diameter. Many distributors lately use thick insulation with a skinny wire beneath to trick patrons. That is particularly problematic when utilizing generic speaker wire for electrical initiatives.Crimp Connectors or TerminalsSelect the precise Crimp Connector. Not all crimp connectors have the identical design, high quality, materials or energy. When doable select a top quality equipment. For insulated terminals, I choose nylon (the translucent ones) over PVC insulation. Seamless or brazed barrels are additionally preferable, as crimping is extra constant.Relying on the job you could choose an insulated barrel, or an uninsulated barrel. For floor wires I have a tendency to make use of uninsulated. Many DIYers choose to make use of uninsulated and add their very own heatshrink later. If you may be pushing the connector to its present limits, uninsulated can also be finest as it’s simpler to get a dependable crimp. However in follow, the choice will rely upon the appliance.This could be an instance of an honest inexpensive crimp connector equipment. There are higher, simply take into account that the prime quality kits get costly, quick. No matter you determine, be certain that to decide on the precise measurement in your wires. Fortunately most crimp connectors are shade coded as follows:

- Purple: 22-16 AWG

- Blue: 16-14 AWG

- Yellow: 14-12 AWG

Wire StrippersSubsequent comes a high quality Wire Stripper. There are numerous differing kinds and codecs relying on the job, so it isn’t actually doable to pick a single fashion.On the fundamental aspect you have got one thing just like the Irwin Wire Stripper/Cutter. It’ll do the job simply nice for affordable so long as you know the way to make use of it appropriately. Although personally what I have a tendency to make use of most lately is the Capri Instruments Automated Wire Stripper/Cutter. I discover it simpler to make use of on wires nonetheless linked to the automobile, because of its pistol-grip design. Additionally, its V-cutter helps strip the wire with out nicking the conductors or ripping the sheath.Crimping InstrumentsAnd at last a very good Ratcheting Crimper. That is most likely a very powerful part, and I wouldn’t suggest skimping. Personally, I take advantage of the Astro Fast-Change Ratcheting Crimping Instrument. It’s wonderful because of its high quality and a number of jaws. However if you happen to’re on a funds you may get an affordable one like this Ratchet Crimping Instrument. The truth that it’s ratcheting and can mechanically launch when the proper stress is reached enormously aids in not over-crimping.A very powerful factor to ensure of is to select one which has the proper jaws/anvils for the job. If you already know you’ll solely be crimping one fashion of terminal, a single mounted jaw is ok. If you’re not sure or would slightly future proof, a mannequin with a number of interchangeable jaws is unquestionably preferable. Even higher if they are often swapped tool-free.Whereas it might be tempting to make use of a Stripper/Crimper/Cutter Mixture software, I’d suggest avoiding them for crimping. Some are respectable, some are junk. Personally, I’d positively go together with the ratcheting fashion contemplating that these days they don’t price that a lot. Utilizing the precise crimping software with a high quality jaw goes to have the largest affect on producing a very good crimp.

Crimp ‘er Up

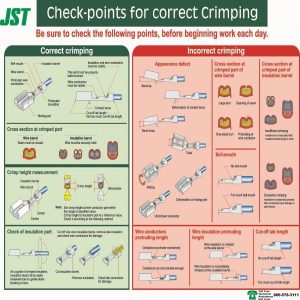

- The stripped wires or remaining insulation ought to be undamaged – Meaning avoiding minimize or nicked strands. The insulation shouldn’t be tapered or torn the place the insulation was eliminated. Ensure the conductors on the finish aren’t minimize at an angle, both. All of those are causes to make use of a very good stripping software.

- There are two kinds of crimping terminals:

- Closed Barrel Terminals – Right here, the portion of the terminal that’s crimped types a closed circle. It’s the fashion sometimes seen with the opaque plastic insulation included with most funds kits. On this mannequin the crimp barrel ought to solely clamp on the uncovered conductors (versus the insulation).

- Open Barrel Terminals – You’ll sometimes discover this sort put in in modular quick-connect plugs. They’ve two units of open “wings”. One crimps over the conductor, and one set crimps on the insulation. Although a bit tougher to persistently crimp, they’re preferable for automotive functions as they supply higher pressure aid. Be sure that the conductor crimp is just crimping the conductor, and the insulation crimp is just crimping the insulation. When crimping such a terminal, utilizing the precise software with the precise jaws in essential. Don’t even have a look at these needle-nose pliers.

- The wire strands ought to barely protrude from the entrance of the wire barrel, however not excessively – This ought to be the case whatever the terminal sort.

- Accurately place the wire within the terminal earlier than crimping – Middle the wire within the terminal and examine its place previous to crimping. If it’s a closed barrel design, you need the seam to be reverse from the detent on the crimping software. That is named “saddling the seam”. It helps keep away from points with the crimp separating on the seam.

- Watch out with over-crimping – Over-crimping a connection work hardens it making it brittle and susceptible to failure. One good thing about ratcheting crimpers is that they’ll mechanically launch after they obtain the correct crimping stress. In fact, don’t under-crimp both since that’s simply as dangerous.

- The place doable, shield the crimp from corrosion – If you’re actually involved with corrosion and moisture wicking, you should use some dielectric grease, conformal coating or liquid electrical tape.

- Add pressure aid when doable – Although crimped terminals cope higher with repeated bending than soldered connections, don’t abuse it. If the wire shall be unsupported and underneath any pressure, at a minimal add some heatshrink as pressure aid. Even higher if it’s the double-walled adhesive selection. That fashion is sturdier and gives some safety from water ingress because of the glue.

- Examine every crimp – Give every crimp a lightweight tug as a fast check. You’d a lot choose it fail now that you simply’re engaged on it, slightly than a month down the street. Additionally, give it a couple of bends to see if that loosens the wire. If performed correctly, it ought to really feel safe and trust-inspiring.

Maintain all of this in thoughts and your connections are prone to outlive the automobile, as most OEM crimps do. So long as you do it proper, there isn’t something to be skeptical about.

What if I Need to Solder a Crimped Connector Anyway?

What about Tinning Wires?

Tinning a wire consists in coating the uncovered stripped finish in tin. That is ceaselessly performed in electronics to assist with later soldering and to stop fraying. It may be past the scope of the “better to crimp or solder” debate, nevertheless it’s price concerning. Nonetheless, to do it or not for automotive functions is questionable, in any case.Per the IPC (Affiliation Connecting Electronics Industries), IPC-J-STD-001 Rev E, web page 13, part 5.1.3, stranded wire shall not be tinned when the wire shall be utilized in:

Mainly if you happen to’ll be crimping or securing it with a screw in a terminal, you shouldn’t be tinning it. The explanations are two-fold. When the screw closes down on the wire it might break the solder joint making it inclined to vibration, loosening and corrosion. A second downside is that tin flows barely at low temperatures which can result in unchecked loosening afterward. I’m positive the truth that introducing much less conductive tin in between the copper and the connector doesn’t assist both.Except you may be soldering the wire to a circuit board later (which might occur, even on a motorcycle – see my decoy alarm mission for GPS trackers), I’d keep away from it. Nevertheless, an exception may be if you’re nonetheless designing and testing a mod and shall be disconnecting/connecting the wire ceaselessly. Then I would tin to maintain fraying at bay. If that isn’t the case, I’d attempt to keep away from it for such a job.

I Must Solder As a substitute of Crimp – Any Ideas?

Okay, so that you’ve learn all of this, and you might be prepared to think about it may not be BS. However…it’s a must to repair an issue now and also you don’t have time to order a correct crimping software. Plus, loads of individuals solder so it might’t be that dangerous. What can we do to keep away from points with a soldered connection down the street?So long as you’re taking the precise precautions, after all soldering is nice sufficient for many duties. The principle issues to ensure of are:

- Be certain that no solder will get underneath the insulation – Use the correct instruments and approach. Bear in mind, solder tends emigrate in the direction of the warmth. And don’t use the soldering iron to immediately soften the solder.

- Utterly immobilize the soldered part – That is specifically essential with splices. If performed, it avoids the connection work-hardening itself to demise. Heatshrink is usually one of the best answer, so long as you intend prematurely. Use two layers or extra if wanted, and adhesive heatshrink is finest since it’s thicker. Electrical tape sucks for this job, however you should use it as a final recourse. There ought to be sufficient pressure aid to maintain the joint from transferring in any respect. In fact, keep away from utilizing solder unsupported in excessive vibration functions.

- Solder isn’t an alternative to a very good mechanical connection – By no means use solder to carry the wires collectively. That’s a recipe for failure. In lots of circumstances doing that is what begins the dialog on if it’s higher to crimp or solder.

- Use the precise measurement soldering iron – Making use of gobs of solder isn’t an alternative to the incorrect software or poor approach. Keep away from utilizing an underneath or over-sized soldering iron. A variable soldering iron is commonly helpful for that reason. If the connection is simply too giant to solder with the software you have got, cease. Crimping or securing with a screw-terminal might be a greater thought.

- Use digital rosin core solder, and clear later – Rosin core solder helps solder elements in lower than very best situations. Meaning soiled and oxidized wiring. Since rosin flux solely turns acidic when heated, it’s sometimes thought of “no-clean”. Nevertheless, engine bays are scorching so I at all times suggest utilizing some cleansing alcohol in a small squirt bottle to wash off the residual flux. And naturally, don’t even think about using acid core plumbing solder.

Is it Higher to Crimp or Solder? – Conclusion

References & Good Reads

- YouTube – Allied Wire & Cable – Automotive Wire & Battery Cable Fundamentals

- YouTube – Allied Wire & Cable – Cable Fundamentals 101: Conductors

- topqa.information – Fundaments Friday – Crimp Vs Solder Connections

- Youtube – EricTheCarGuy – How To Crimp Electrical Connectors

Last, Wallx.net sent you details about the topic “Why is soldering not good for fixing cars❤️️”.Hope with useful information that the article “Why is soldering not good for fixing cars” It will help readers to be more interested in “Why is soldering not good for fixing cars [ ❤️️❤️️ ]”.

Posts “Why is soldering not good for fixing cars” posted by on 2022-04-07 16:22:56. Thank you for reading the article at wallx.net