Why is glycol used as coolant in electric vehicles

Future analysts will see 2019 as the ground-breaking year in the field of electric driving, in fact in terms of recent stylings. In 2018, nearly all of the major manufacturers were offering mass-market battery electric vehicles, along with PSA Group and Volkswagen. In China, the push towards BEVs continues unabated, with additional auto groups launching new, all-electric sub-brands. In Japan, Toyota and Mazda are notoriously hesitant to finally acquire on the BEV gang, while the meteoric rise of Tesla’s Mannequin 3 has claimed there’s no sign of slowing down. gasoline in the cylinders and friction between transmission components generate warmth, which is managed by lubrication, coolant and heating, airflow, and refrigeration methods. However, ICE engines prefer it to burn, so these methods only cool the engine down to 95 degrees Celsius during normal operation. also produce a lot of warmth, however they like to be cool. Adequate cooling, especially of the battery pack, is crucial, as Tesla discovered its price tag after a series of fires in its cars. Lubrizol means that thermal management is also more difficult for hybrids because the operating temperatures are too high for the ICE and the desired low temperatures for the battery, e-motor and inverter. Try it first on a battery, its effectiveness depends on maintaining an optimal temperature. Extremes of incineration or freezing affect efficiency, longevity, various circumstances and costs. Lithium-ion EV batteries generate energy by chemical reaction, and the colder the reactant is, the slower it reacts and less energy is produced. 3 Pin Chilly takes more time and has a decreasing and changing acceleration. A scorched battery will degrade sooner and melt lithium from the anode after self-discharging.4 This slender window requires a battery management system that continuously monitors heating and cooling and maintains the cells. between 20 degrees C and 40 degrees C. There are only a few cooling strategies along with, in most BEVs, a liquid coolant, such as a glycol-water blend (Tesla Mannequin 3, Jaguar I-Tempo, Audi). E-tron) or they are air-cooled (Nissan Leaf, VW e-Golf) or use refrigerants (BMW i3) Electronic engine cooling is also key to ensuring performance. tallest. World efficient thermal management between stator and rotor in electronic motors is very important and bearings can reach 150 C and can reach 170 C in short time period. e-motor and frequency converter, which converts DC battery power into AC power for the e-motor, along with forced air cooling, shaft shaft rotor cooling, outer jacket liquid cooling and mixture Combination of both, oil spray or dielectric immersion. Read more: Why did she act interested the first few days of our stay and then ghost me? The last two parts can use mineral oil. However, there is a consensus that extra work is needed each to optimize cooling efficiency in EVs right now and to meet the desires of tomorrow’s vehicles. Ford considers that there is little knowledge in the literature about the heat-reducing properties of current lubricant base oils. The company says that additional analysis must be completed on the current underlying stock and that final {that a} answers may require exploration of recent liquids.

Choice of coolant

Contents

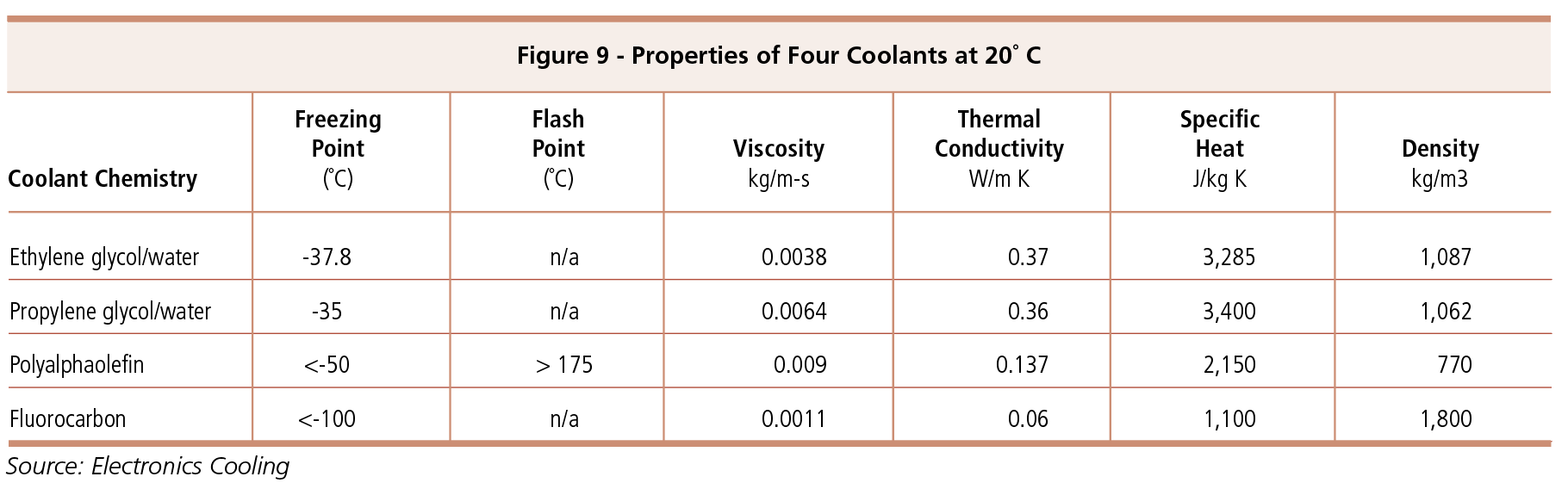

The cooling efficiency of any liquid depends on its thermal conductivity, its ability to generate warmth (referred to as specific warming capacity – the amount of warmth needed to raise the temperature of the liquid). a substance per unit mass) and its viscosity, and has a achievable Current Selectable Liquid Quantity. Surface warmth is an important consideration for collecting any cooling fluid. Normal water comes out at the top, however the water cannot be used on its own and so it is mixed with glycol (a substance in alcohol production) to prevent it from freezing or boiling. However, these mixtures are superior to petroleum in their ability to keep warm.Viscosity, a simple measure of how well a fluid will circulate, is another important issue. Low viscosity fluids are preferred, however this must be balanced by two components: volatility – the tendency of the oil to evaporate at excessive warmth, to keep out potential fires – and density, which determines how much fluid you want, as this can affect the overall weight of the vehicle. These ingredients must be considered, however, the query remains if oil-based options can compete with water-glycol options.

Glycol

The glycol-water combo is an inexpensive, well-established coolant that is sometimes composed of about 50% glycol, 45% water, and 5% ingredients, along with antioxidants, antifreezes, and antioxidants. Inhibits corrosion, solvents and dyes. Glycol has good warmth conversion properties, with a thermal conductivity in the region of 0.35 watts per kelvin5 meter compared to 0.13 W/m Ok for a traditional base stock, such as polyalphaolefin or a fluorocarbon refrigerant at 0.06 W/m Ok. It also has exceptional warmth retention that outperforms various liquid options, such as PAO. The downside of glycol-based coolant is that it loses effectiveness over time, is prone to contamination and corrosion, and is a serious maintenance commodity for a BEV. Various downsides are its incompatibility with existing additive chemistry, as well as electrical conductivity considerations, according to analysis by Afton Chemical.

Mineral oil and PAO

Oil is lighter than glycol-water and contaminant and corrosion problems can be greatly minimized. This means the liquid will last longer and not lose its effectiveness over time. Also, one should keep in mind that an oil-based answer can potentially extend life and cut maintenance, as well as improve driving expertise. It can also provide added efficiency and direct cooling capabilities that water-glycol cannot. Polyalphaolefins can be another and have the benefit of being a dielectric fluid. Afton also found that treating the additive with an electrical charge had no effect on thermal performance. Esters, or Group V oils, have demonstrated some superior results, but are more costly. This will probably be a key issue for the oil trade, as battery cooling could change into a profitable outlet for their commodities, however provided it can carry a larger and more cost-effective joint answer and the space is ripe for innovation.

Direct or skew cooling

The water-glycol and air-cooling methods are oblique cooling. Glycol is pumped by pipes surrounding the battery or by air circulating around the battery. Air-cooling methods are the only, most cost-effective answer, however they are not capable of addressing the needs of huge EV batteries and due to this fact provide most of the benefits. type and life cycle. This is especially true when considering the variation of ambient temperature around the specialist vehicle and the floor space that must be cooled. Reviews by the US National Renewable Vitality Laboratory and the National Living Distribution Community Know-how Analysis in China have found that air fresheners want three times more vitality. compared with liquid cooling strategies to take care of the identical overall temperature.6

Last, Wallx.net sent you details about the topic “Why is glycol used as coolant in electric vehicles❤️️”.Hope with useful information that the article “Why is glycol used as coolant in electric vehicles” It will help readers to be more interested in “Why is glycol used as coolant in electric vehicles [ ❤️️❤️️ ]”.

Posts “Why is glycol used as coolant in electric vehicles” posted by on 2022-05-02 22:06:25. Thank you for reading the article at wallx.net