What Is A Split Point Drill Bit

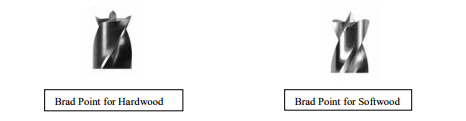

Drill bits come in a variety of point configurations with each designed for specific uses. Each type of point design has its own uses. There are 6 types of drill points: Read: what is a point drillStandard industrial drill or conventional drill – A standard point drill or a v-drill with an included angle of 118 degrees with cutting angles suitable for cutting metal. Standard point drills specifically designed for cutting wood typically have a longer sharp angle (ie 80 degrees). A longer 80’s point can sometimes work better on wood if you’re having problems with excess debris on the backside after drilling through the wood. The 118-degree point is designed to be a versatile spot and will cut almost any material. If the standard drill bit does not give the desired results, one of the other types of drill may be needed.Point Separation Drill – this type of bit usually has corner points including 135 degrees and is designed for cutting metal. The standard drill has two cutting edges but there is a section in the center of the drill called the chisel edge that doesn’t actually cut, but chisel the material. The chisel edge can also cause the drill bit to traverse the material when you are trying to start cutting the drill at a specific location. The Split Point drill has two additional edges that are sharpened into the chisel edge, making the entire drill one long cutting edge. This reduces the amount of pressure required to make the drill bit cut. The Split Point is also self-centering which means the drill starts to cut exactly where it comes into contact with the material. These features are designed for drilling in metal but may be beneficial in some harder woods.Brad-Point drill bit – Why use a brad-point drill? A sharp tip drill should provide the cleanest, straightest, and most accurate sized hole in wood of any reasonably priced tool on the market today. The bar in the center of the point allows for precise positioning at the start of a hole even when the hole is not 90 degrees from the surface. Outer edges thin the grain and leave a clean edge around the opening eliminating the need for sanding. The branch continues to cut the wood while drilling and creates a hole of the correct size. In most woods, drill bits also help create cleaner edges when drilling through the back of the wood. We have worked with thousands of customers to manufacture Brad Point Drills to meet their needs. We offer Brad Point Drills in any size including Wire Gauge, Letter Size, Metric Size and longer or shorter lengths. If there is a need for a size not mentioned in these, we can take standard sizes and grind and/or cut to the special size needed. We use industrial quality High Speed Steel domestic drill bits designed for metal cutting and re-machine them for wood cutting. As a result, the Brad Point Drill is made tolerable when it comes to metal working with cutting edges that last longer than standard woodworking tools. There are basically two types of brad point designs that we use. One works best on hardwoods and the other works best on softwoods. Brad Point drills specially designed for softwoods generate too much heat and are difficult to push in hardwoods. Although the Brad Point Drill is specifically designed to cut hardwoods that will cut softwoods, the aggressive cutting blades tend to lift the weak fibers of the softwood, resulting in a torn edge around the opening. All the Brad Point Drills that we manufacture and display in our catalog are specifically designed for hardwoods and work well for most applications.

Last, Wallx.net sent you details about the topic “What Is A Split Point Drill Bit❤️️”.Hope with useful information that the article “What Is A Split Point Drill Bit” It will help readers to be more interested in “What Is A Split Point Drill Bit [ ❤️️❤️️ ]”.

Posts “What Is A Split Point Drill Bit” posted by on 2021-09-01 21:08:07. Thank you for reading the article at wallx.net