Useful information on positive displacement pumps

Useful information about positive displacement pumps

What is a positive displacement pump?

Contents

A positive displacement (PD) pump moves fluid by continuously enclosing a fixed volume and moving it mechanically through the system. Pump operation is cyclic and can be driven by pistons, screws, gears, rollers, diaphragms or vanes.

How does a positive displacement pump work?

While there are many styles of pumps, most can be grouped into two categories: reciprocating and rotary.

Reciprocating positive displacement pump

Reciprocating positive displacement pumps operate by a repetitive back and forth motion (stroke) of the piston, plunger or diaphragm (Figure 1). These cycles are called reciprocating motion, in a piston pump the first stroke of the piston creates a vacuum, opens the inlet valve, closes the outlet valve and draws liquid into the piston chamber (suction stage) . When the piston movement reverses, the inlet valve, which is now under pressure, is closed and the outlet valve opens to allow the liquid contained in the piston chamber to be discharged (compression phase). The bicycle pump is a simple example. Piston pumps can also be dual acting with inlet and outlet valves on both sides of the piston. While the piston is sucking on one side, it is compressing on the other. More complex radial versions are commonly used in industrial applications. The volume of liquid moved by the piston pump depends on the cylinder volume; In a plunger pump it depends on the plunger size. Seals around pistons or pistons are important to maintain pump operation and avoid leaks. In general, a plunger pump seal is easier to maintain because it rests at the top of the pump cylinder while the seal around the plunger continuously moves up and down inside the pump chamber. or plunger to move the fluid. By expanding the diaphragm, the volume of the pump chamber is increased and the liquid is drawn into the pump. Compression of the diaphragm reduces the volume and pushes some of the fluid out. Diaphragm pumps have the advantage of being a closed system making them ideal for pumping hazardous liquids. This can cause harmful vibrations during installation and often some form of damping or smoothing is used. Impulses can also be minimized by using two (or more) pistons, pistons or diaphragms with one piston in the compression stage while the other pump is sucking. . By varying the speed or stroke length, a measured quantity of the pumped liquid can be provided.

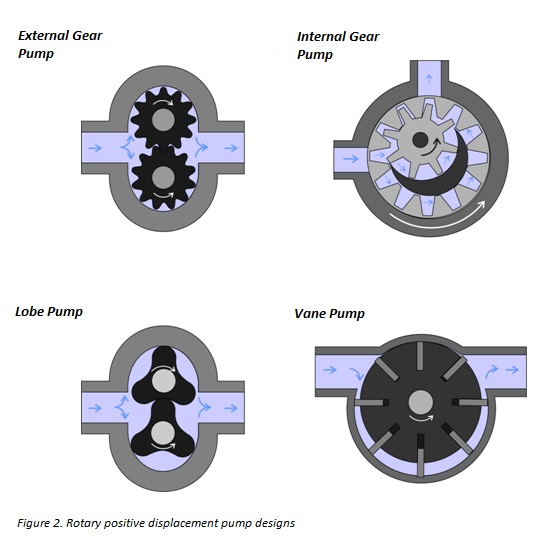

Rotary positive displacement pump

Read more: what is op in anime | The leading Q & ARotary positive displacement pumps use gear or rotary gear operations to transfer fluid, rather than the back and forth movement of a reciprocating pump. The rotating element develops a liquid seal with the pump housing and generates suction at the pump inlet. The liquid, drawn into the pump, is enclosed in the teeth of the gear or its rotating gear and is routed to the discharge unit. The simplest example of a rotary positive displacement pump is a gear pump. There are two basic designs of gear pumps: external and internal (Figure 2) An external gear pump consists of two interlocking gears supported by separate shafts (one or both shafts). this can be driven). The rotation of the gears holds the fluid between the teeth moving it from the inlet, out to the discharge line, around the housing. No fluid is transferred back through the center, between the gears, because they are interlocked. The close tolerances between the gears and the housing allow the pump to develop suction at the inlet and prevent liquid from leaking back from the discharge side. Leaks or “slips” are more likely to occur with low-viscosity liquids. An internal gear pump works on the same principle but two interlocking gears are of different sizes with one rotating inside the other. The cavity between the two gears is filled with fluid at the inlet and is transported around the outlet, where it is ejected by the action of the smaller gear.

What are the main features and benefits of a positive displacement pump?

There are two main families of pumps: positive displacement and centrifugal. Centrifugal pumps have higher flow capacity and can work with liquids of lower viscosity. In some chemical plants, 90% of pumps in use will be centrifugal pumps. However, there are some applications where positive displacement pumps are preferred. For example, they can handle liquids with higher viscosity and can operate at high pressures and relatively low flows more efficiently. They are also more accurate when metering is an important factor to consider.

What are the limitations of a positive displacement pump?

Read more: What is Santa Claus called in louisiana In general, positive displacement pumps are more complicated and difficult to maintain than centrifugal pumps. They are also incapable of producing the high flow rates characteristic of centrifugal pumps. Positive displacement pumps are less capable of handling liquids with lower viscosity than centrifugal pumps. To generate suction and reduce slippage and leakage, the rotary pump relies on a seal between its rotating parts and the pump housing. This is greatly reduced with low viscosity fluids. Similarly, it is more difficult to prevent slippage from the valves in reciprocating pumps with low viscosity supplies because of the high pressure created during pumping. Impulsions can cause noise and vibration in the piping system and cavitation problems, which can eventually lead to damage or failure. Overclocking can be reduced by using multiple pump cylinders and dampers, but this requires careful system design. Centrifugal pumps, on the other hand, produce a smooth, steady flow. The reciprocating pump movement can also be a source of vibration and noise. Therefore, it is important to build a strong foundation for this type of pump. Because of the high pressure created during the pump cycle, it is important that the pump or discharge line have some form of pressure relief in the event of a blockage. Centrifugal pumps do not need overpressure protection: the liquid is simply recirculated in this case. Granules containing high levels of abrasive solids can cause excessive wear on components of all types of pumps and especially valves and seals. Although positive displacement pump components operate at significantly lower speeds than centrifugal pump components, they are still susceptible to these problems. This is particularly the case with reciprocating and reciprocating pumps and gear pumps. With this type of feed, a telescopic, screw or diaphragm pump can be suitable for more demanding applications. The following table summarizes the capabilities of centrifugal and positive displacement pumps.

Pump comparison: Centrifugal and positive displacement

Asset Centrifugal Positive displacement Effective viscosity range Effectiveness decreases with increasing viscosity (up to 200 Cp) Efficiency increases with increasing viscosity Pressure resistance Pressure-variable flow at constant pressure) Continuous pulse cutting (separation of emulsions, slurries, bio-liquids, food) High speed motor damages sensitive media with low internal velocity. Ideal for pumping shear-sensitive fluids

What are the main applications of positive displacement pumps?

Positive displacement pumps are generally used to pump highly viscous liquids such as oils, paints, plastics or foods. They are preferred in any application where precise dosing or high pressure output is required. Unlike centrifugal pumps, the output of positive displacement pumps is not affected by pressure so they also tend to be preferred in any situation where the supply is uneven. Most are self-priming. Pump type PD Register Featured Piston pump Water – high pressure washing; other low viscosity liquids; oil production; spray painting Piston action with piston(s) sealed with o-rings Piston pump Piston operation with piston(s) sealed with packing Diaphragm pump Used for dosing or dispensing; spraying / cleaning, water treatment; oil painting; corrosive liquids Shellless, self-priming, low flow and high pressure resistant Gear pump Pumps high viscosity liquids in the petrochemical, chemical and food industries: oil, paint, food Mesh gears providing rotary pump operation Lobe pumps Chemical and food industries; sanitary, pharmaceutical and biotechnological applications Low cut and wear. Easy to clean or disinfect Screw Pump Oil production, transmission and fuel injection; Irrigation Fluid moving axially reduces turbulence; high flow capacity Vane pump Low viscosity liquid; automotive powertrains; fuel filling and transmission; beverage dispensers Resistant to entrained solids and vane wear. Design allows variable output

Summary

A positive displacement pump moves fluid by repeatedly enclosing a fixed volume, with the help of seals or valves, and moving it mechanically through the system. Pump operation is cyclic and can be driven by pistons, screws, gears, lobes, diaphragms or vanes. There are two main types: reciprocating and rotary. Positive displacement pumps are preferred for applications involving highly viscous liquids such as thick oils and slurries, especially at high pressures, for complex feeds such as emulsions, foods or biological fluids. study and also when precise quantification is required. Read more: What happens around quotes

View our full range of pumps

Send us your request

Last, Wallx.net sent you details about the topic “Useful information on positive displacement pumps❤️️”.Hope with useful information that the article “Useful information on positive displacement pumps” It will help readers to be more interested in “Useful information on positive displacement pumps [ ❤️️❤️️ ]”.

Posts “Useful information on positive displacement pumps” posted by on 2021-08-24 08:31:19. Thank you for reading the article at wallx.net